"If the nozzle is selected correctly, the efficiency will be doubled."

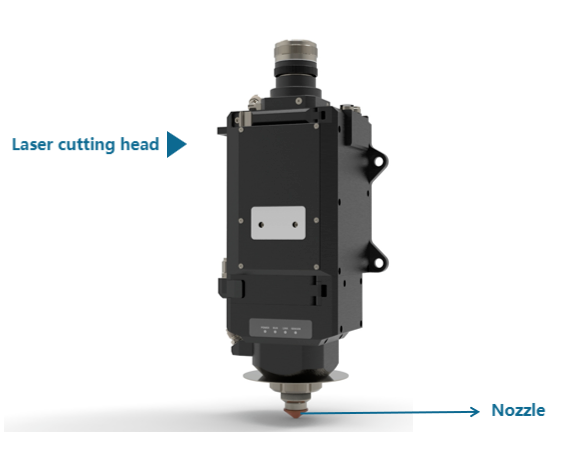

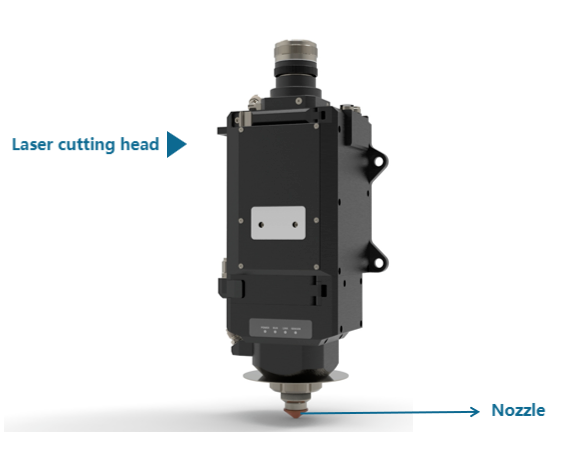

Although it is a seemingly inconspicuous small part, its function is not small. It is necessary to resist the upward rebound of debris such as molten stains, and to control the gas diffusion area and size. Therefore, the quality of the nozzle is an important factor in determining the quality of the cutting. One of the factors, today we will talk about how to choose the "nozzle".

Q1:

Is there a big difference between nozzles of different quality?

The difference is very big, because the material and precision of the nozzle play a decisive role in the conductivity, heat conduction effect, difficulty of debugging, and the protection of the laser head. A good nozzle can protect the optical lens inside the cutting head and release the auxiliary gas to the surface of the cutting material And in the kerf, guide the gas to assist the cutting and take away the slag, leaving a clean cut, so the quality of the nozzle directly affects the life of the cutting head and the quality of the cutting workpiece.

Generally speaking, the price of the original nozzles of the cutting head is relatively high, which also makes the nozzles sold by third parties very popular, but not every third-party manufacturer has the production capacity of such consumables.

In the recent years when the price war of fiber lasers has been fierce, the prices of laser accessories have also become lower and lower. Blindly pursuing low prices while ignoring quality will not be worth the candle.

Q2:

What are the consequences if the selection is improper?

If the nozzle is not designed and maintained properly, and the processing accuracy is not enough, the flow rate of the gas will be weakened, and the direction of the airflow will become unstable, which will affect the melting of the material during the cutting process and cause melt stains. Cutting thicker plates may even result in failure to cut.

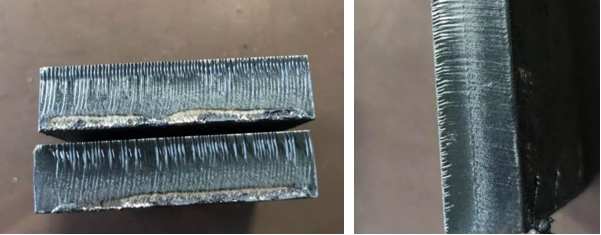

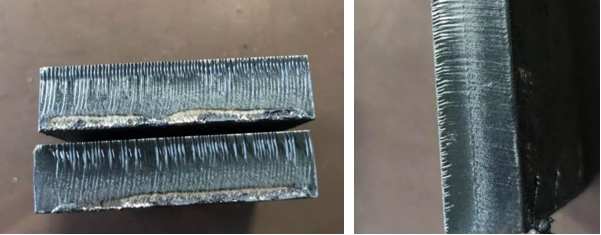

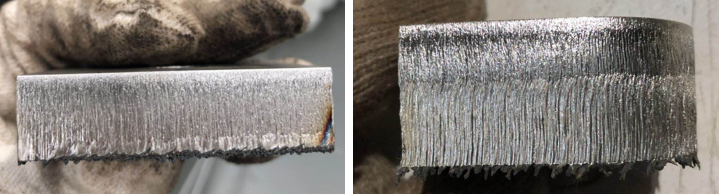

Nozzle selection too large

Upper stripes and lower drag lines (left)

Upper striations are rough with teeth (right)

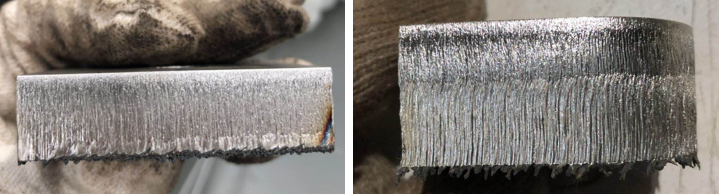

Nozzle selection too small

Insufficient cutting (left)

Cut layering (right)

Q3:

What types of nozzles are there?

There are currently two main types of nozzle designs: "low velocity nozzles" (gas velocity less than the speed of sound) and "high velocity nozzles" (gas velocity close to the velocity of sound). Factors affecting nozzle performance are cutting head cavity air pressure, nozzle diameter, nozzle internal shape and nozzle outlet shape.

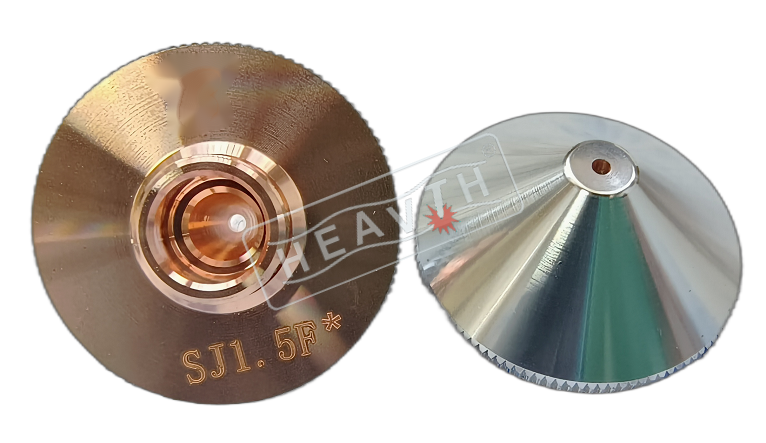

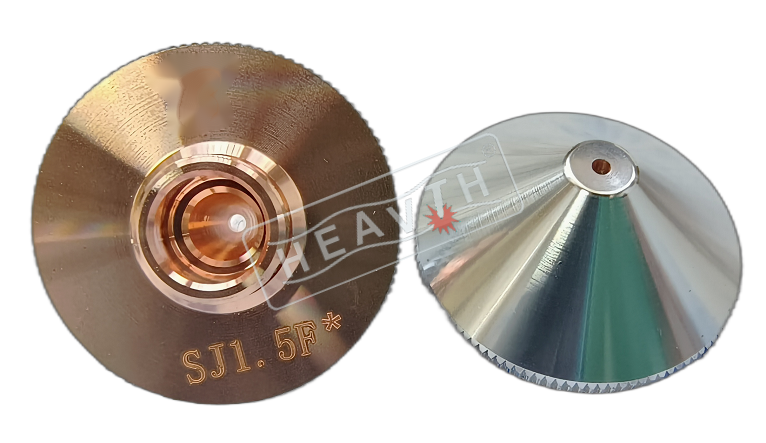

High-speed double-layer nozzle and storm single-layer nozzle

The working principle of the high-speed nozzle is the same as the exhaust principle of rockets and jet engines, which accelerates the gas entering the nozzle, so the high-speed nozzle can produce better results for cutting viscous materials.

However, if an ordinary low-speed nozzle is used, the air pressure on the surface of the workpiece will fluctuate greatly with the change of the cutting height, resulting in an unsatisfactory cutting effect.

Q4: How to choose a nozzle?

It can be selected from the following aspects:

Processing requirements: single-layer nozzles used in laser equipment are mainly used for nitrogen cutting of stainless steel and aluminum plates; double-layer nozzles are mainly used for oxygen cutting of carbon steel.

Material: There are two commonly used materials for nozzles - copper and brass. The electrical conductivity and thermal conductivity of copper are better than that of brass.

Size: The diameter of the nozzle determines the flow rate of the gas and the shape of the gas field. Generally, when cutting a thin plate below 3mm, it is recommended to use a nozzle with a diameter of 1mm, while for a sheet above 3mm, it is recommended to choose a nozzle with a diameter of 1.5mm. The recommended diameter for cutting a sheet above 10mm 2mm or more nozzles.

Processing accuracy: A good laser head nozzle should have a concentricity of 0.03mm, and a nozzle with a size below 1.0mm should have a concentricity of 0.02mm. The high-precision concentricity nozzle can not only reduce the pre-adjustment in the processing process, but also effectively prevent the high-energy laser from hitting the inner wall of the laser head, thereby avoiding damage to the laser head.

Introduction of common nozzles

Q5: How to install and debug the nozzle?

Nozzle installation steps

1. Unscrew the nozzle;

2. Replace with a new nozzle and retighten it with appropriate force;

3. After replacing the nozzle, the capacitance calibration must be done again.

Take the Spur 12kW cutting head as an example, the focal point is matched with the nozzle (0 focal point must be calibrated):

Double layer 1.2E: cutting 3mm-12mm carbon steel plate, focus between 5-11

Double 1.4E: Focus 9-14

Double 1.6E: Focus 11-16

Double Layer 1.8E: Focus 13-18

SP Monolayer 1.2: Focus 8-13

SP Monolayer 1.4: Focus 10-15

SP Monolayer 1.6: Focus 12-17

SP Monolayer 1.8: Focus 14-19

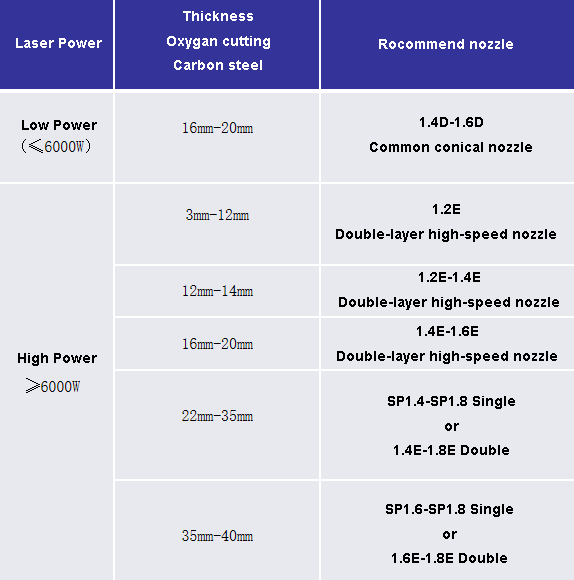

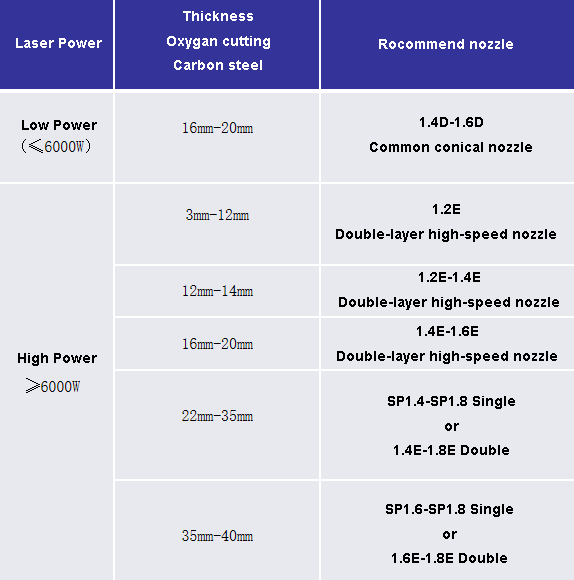

Recommended nozzles for common use

Nowadays, the quality of nozzles in the market is uneven. When purchasing, it is recommended to carefully screen according to the above content, and choose a reliable supplier for purchase.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Azərbaycan dili

Беларуская мова