Equipment overview

As the manufacturing industry continues to increase its demand for efficient and high-quality welding processes, industrial arc welding robots have emerged and become the core equipment in intelligent production lines. Welding robots combine advanced welding technology with high-precision robotic arm systems, and have the characteristics of fast welding speed, high weld quality, and high degree of automation. They are suitable for a variety of metal materials such as stainless steel, carbon steel, and aluminum alloys, and are widely used in automobile manufacturing, rail transportation, engineering machinery, sheet metal processing, new energy and other fields.

Key Features:

High-precision welding

Using industrial digital welding machines, deep-penetration welding is achieved, the weld is firm, the shape is beautiful, and the heat-affected zone is small.

Fully automated intelligent operation

Through offline programming or teaching pendant operation, multi-station, multi-track automatic welding is achieved, greatly improving production efficiency and consistency.

Strong flexibility and wide adaptability

The welding path and parameters can be flexibly adjusted according to different workpiece shapes and materials, and adapted to the welding needs of complex structures and special-shaped parts.

Stable and reliable, reducing labor costs

Long-term continuous operation, stable quality, significantly reducing dependence on highly skilled welders, and reducing labor and management costs.

Intelligent monitoring and remote maintenance

Equipped with an intelligent system, it can monitor welding quality and equipment status in real time, support remote diagnosis and maintenance, and improve the intelligence level of the production line.

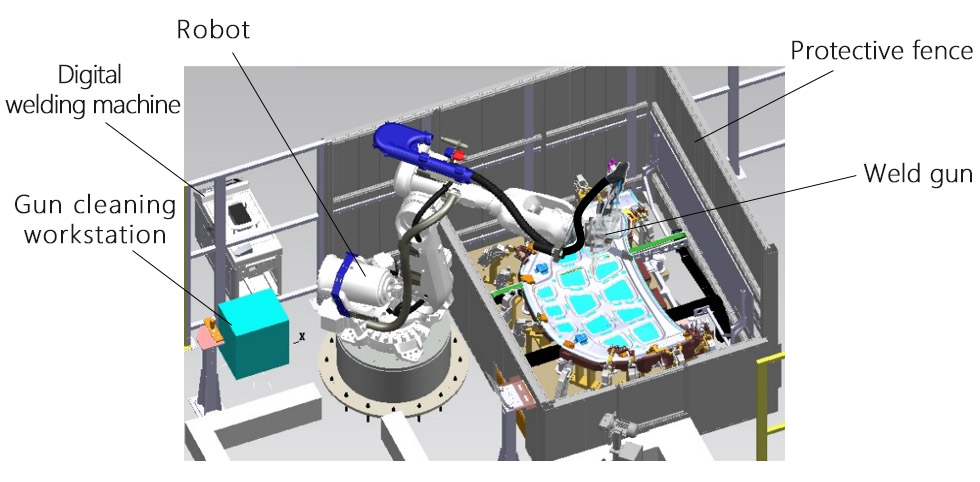

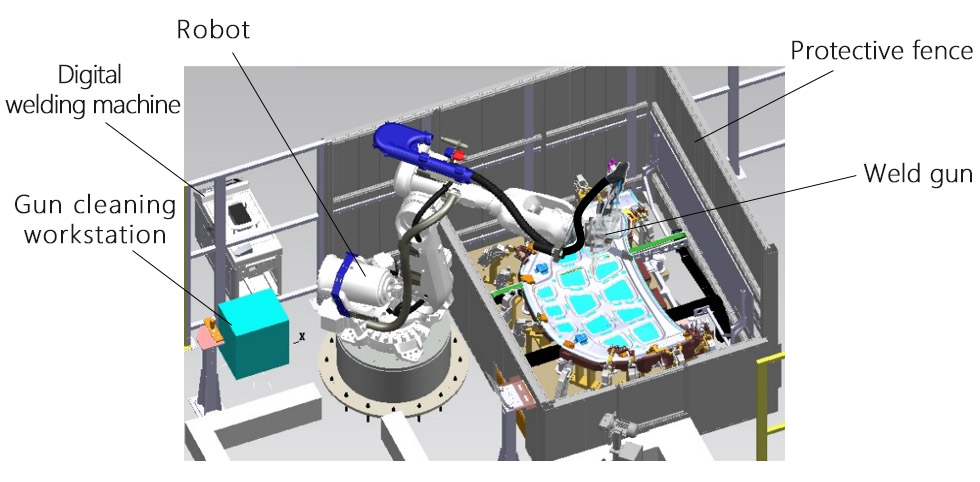

System Composition:

The automatic welding robot system consists of an industrial robot, a digital welding machine, a robotic welding gun, an intelligent wire feeder, a control system, a dust removal system and safety protection facilities.

Industrial Robots:

Employs a dedicated industrial robot for arc welding, with integrated arc welding processes and algorithms for underlying optimization of the robot welding process. Utilizing an advanced servo control system, it achieves high-precision motion. Its compact structure and high-rigidity, lightweight body enable rapid response and low-inertia movement.

Robots Parameters:

Model | BR0805A | BR1510A | BR1820A | BR2013A | BR2110A | BR3030A |

Arm range | 940mm | 1500mm | 1850mm | 2000mm | 2100mm | 3021mm |

Load rates | 5kg | 10kg | 20kg | 13kg | 10kg | 30kg |

Repeat accuracy | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.05mm | ±0.07mm |

Input power | 3.67kVA | 5kVA | 5.87kVA | 6.38kVA | 6.48kVA | 5.07kVA |

Weight | 53kg | 150kg | 230kg | 385kg | 230kg | 783kg |

HMI | Touch screen teach pendant |

Control box | Robot welding dedicated control system |

Digital welding machine:

Ehave series digital welding machine is an industrial digital welding machine with full digitalization, 100% duty cycle, stable pulse control and other features. It is widely used in efficient welding of various materials such as carbon steel, stainless steel and aluminum alloy. It has strong versatility and precise control capabilities, meets different welding needs, provides stable welding performance, and is particularly suitable for industrial, manufacturing and automated welding applications.

Welding Machine Parameters:

Model | Ehave2 CM350R | Ehave2 CM500R | Ehave2 CM630R | Ehave2 PM400R | Ehave2 PM500R |

Functions | CO2/MAG/MIG | CO2/MAG/MIG | CO2/MAG/MIG | CO2/MAG/MIG | CO2/MAG/MIG |

Welding Current | 30~350A | 30~500A | 30~630A | 30~400A | 30~500A |

Welding Voltage | 12V~31.5V | 12V~39V | 12V~44V | 12V~34V | 12V~39V |

No-load Voltage | 60V | 73V | 78V | 76V | 76V |

Weldable Materials | CS, SS | CS, SS | CS, SS | CS, SS, AL | CS, SS, AL |

Welding Process | DC | DC | DC | DC, Single and double pulse, DP | DC, Single and double pulse, DP |

Duty Cycle | 350A@100% | 500A@100% | 630A@100% | 400A@100% | 500A@100% |

Input Power | 13.1KVA | 23.1KVA | 32.4KVA | 16.2KVA | 23.1KVA |

Input Voltage | AC380V 3P±25% | AC380V 3P±25% | AC380V 3P±25% | AC380V 3P±25% | AC380V 3P±25% |

Robot welding gun:

1. Unique airflow design effectively protects the conductive nozzle and prevents splashing, which can achieve long-term continuous welding.

2. Integrated design, fast welding speed and high efficiency.

3. Suitable for a variety of metal materials (such as carbon steel, stainless steel, aluminum alloy).

4. Stable welding quality and beautiful forming.

5. Matching robot-specific intelligent wire feeder, accurate wire feeding.

|

|

Robot welding gun | Wire feeder for robot |

Three-in-one gun cleaning station:

In robot welding, the gun cleaning station is used to clean the welding gun to keep the welding gun head clean, ensure the welding quality and the stable operation of the robot. "Three-in-one gun cleaning station" refers to an automated station that integrates three functions of gun cleaning, detection and maintenance:

Gun cleaning function: automatically remove spatter, welding slag or oxides on the welding gun nozzle to prevent blockage and ensure the normal nozzle gas and wire delivery of the welding gun.

Detection function: can detect the wear state of the welding gun, the deformation of the gun nozzle, or the guide parts in the welding gun in real time.

Maintenance function: includes lubrication, coating or simple robot gun replacement operations to extend the service life of the welding gun.

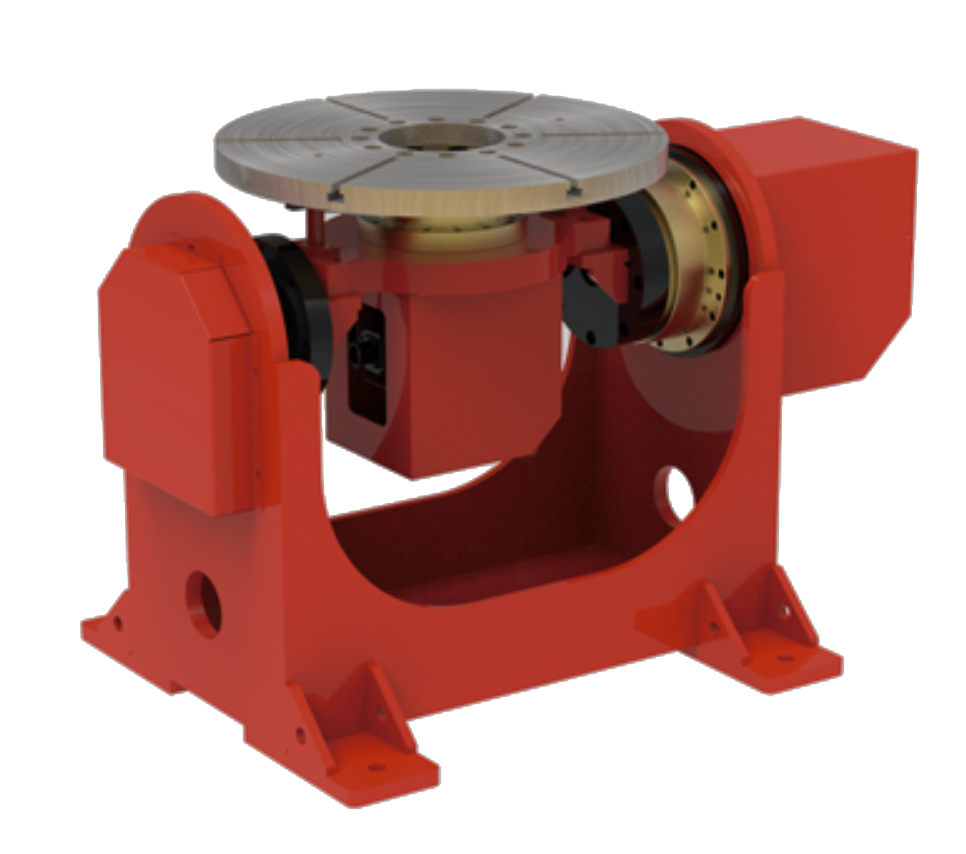

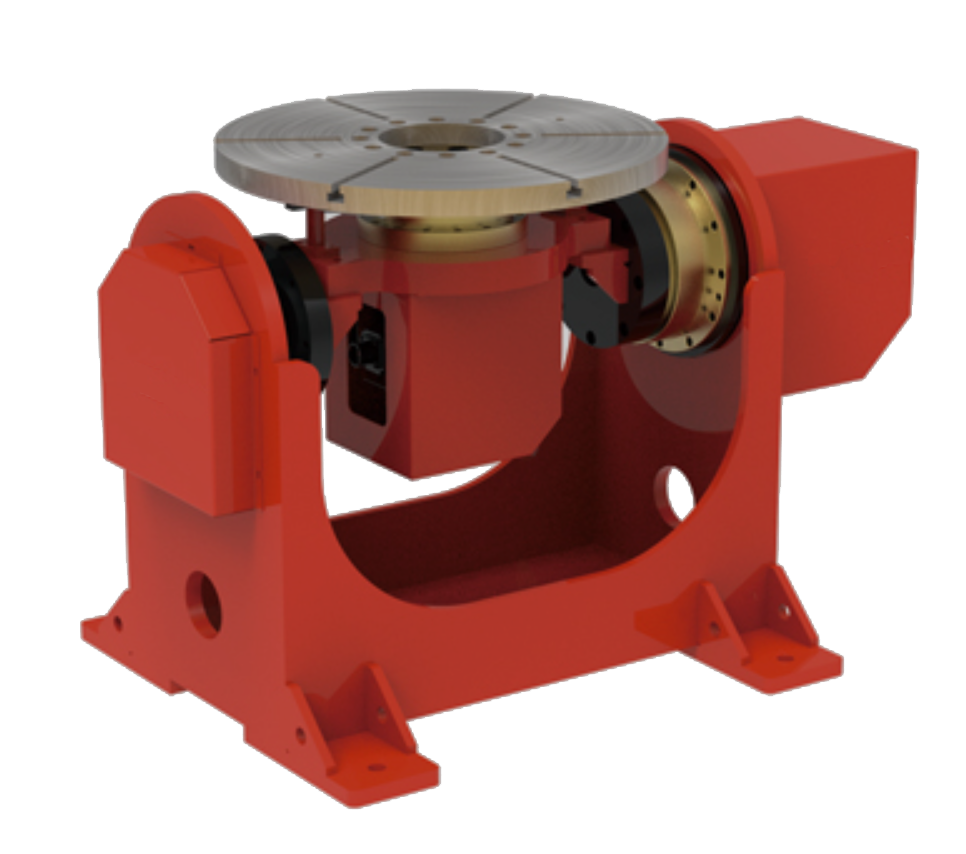

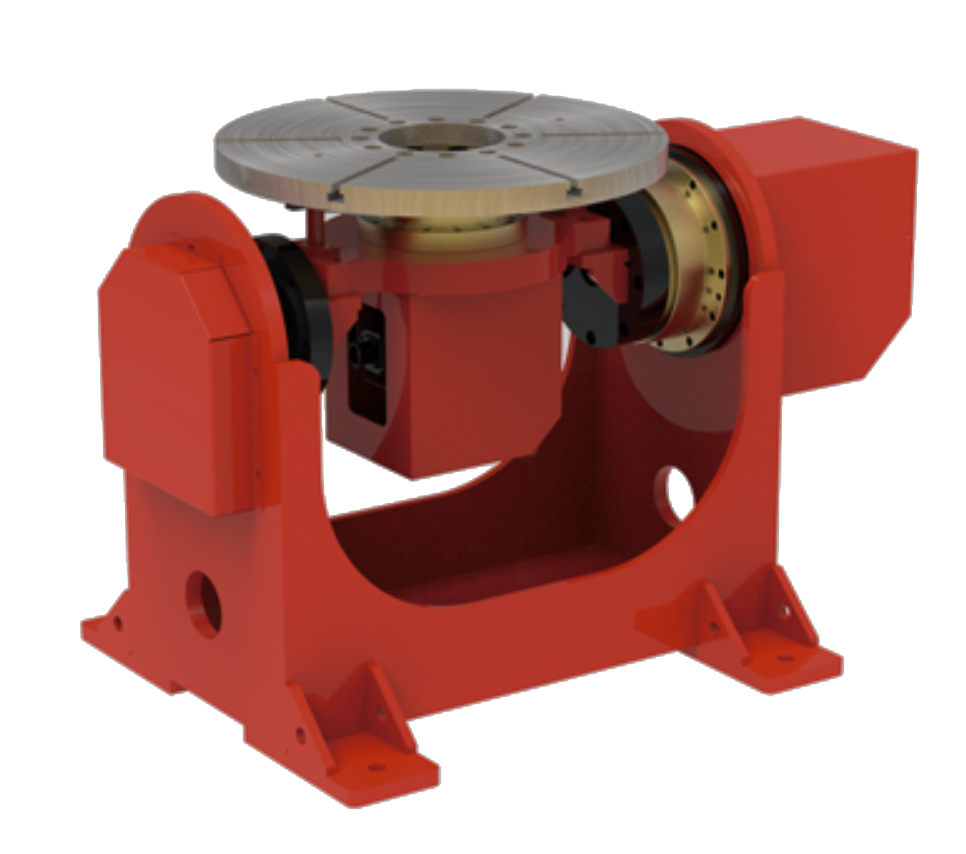

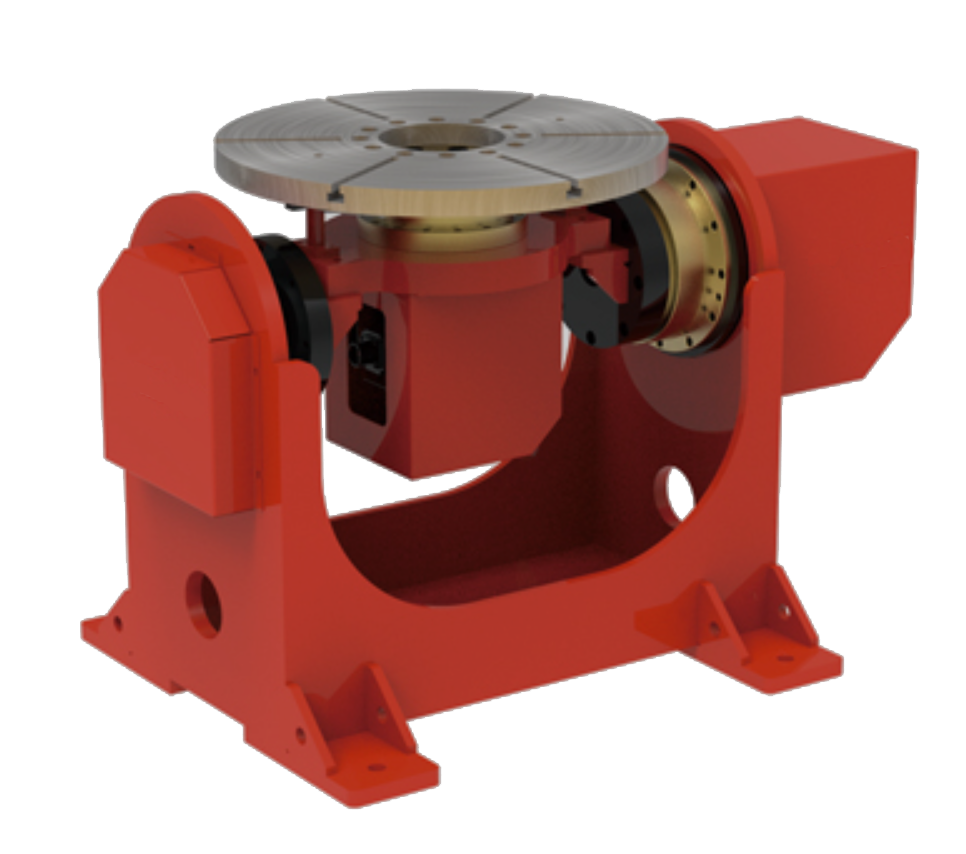

High-precision positioner (optional):

The welding positioner is an efficient auxiliary equipment used in conjunction with the robot welding system. Its main function is to optimize the welding angle and welding trajectory by accurately rotating, flipping or positioning the workpiece, thereby achieving high-quality and efficient automated welding operations.

The positioner can freely adjust the welding posture according to the structural characteristics of different workpieces. In conjunction with the robot welding gun, it greatly improves the welding accuracy and finished product consistency. It is an indispensable and important equipment for achieving full-position welding of complex workpieces.

Welding robot ground rail (optional):

The welding robot ground rail (also known as ground rail, robot slide) is a key expansion unit to improve the robot's operating range and flexibility. By installing a linear rail on the ground, the robot can move along the track with high precision, achieving continuous automated welding in multiple stations and multiple areas, greatly improving the flexibility and efficiency of the production line.

The ground rail system not only expands the robot's working radius, but can also be used with a variety of welding processes such as laser welding, arc welding, and spot welding. It is an indispensable and important equipment in the intelligent welding production of large workpieces and large components.

Standard Configuration:

No. | Name | Description | Quantity | Photo |

1 | Industrial Robots | Sinsun SR12A | 1 set |

|

2 | Digital welding machine | MEGMEET CM500R | 1 set |

|

3 | Robot welding gun | Loyee | 1 set |

|

4 | Wire feeder | Wire feeder for robots | 1 set |

|

5 | Gun cleaning station | Three-in-one | 1 set |

|

6 | Positioner (optional) | High-precision positioner | 1 sets |  |

7 | Ground rail (optional) | Servo driven ground rail | 1 set |

|

Welding sample:

Equipment After-Sales Service Terms

1. Installation and commissioning

a. Our technical staff assists customers in the installation and commissioning of equipment. After the goods arrive at the delivery site of the buyer, our engineers provide video technical guidance for the installation and commissioning of the equipment, and assist customers in completing the installation, commissioning, technical indicator testing, training, and delivery of the equipment.

b. Remote installation and commissioning must be completed within the period specified in the contract. All equipment provided in the contract is responsible for docking and completing installation and commissioning by our company. After the equipment is installed and commissioned, the customer shall conduct a self-inspection of the equipment and ensure that all technical indicators meet the technical requirements.

c. For customers who need on-site installation and training, the customer shall bear the transportation costs to and from the commissioning site, and the technical staff service fee is US$200 per day, calculated from the departure of the company to the return (i.e. on-site service time + round-trip transportation time).

2. Packaging and transportation

a. Standard export packaging, suitable for long-distance sea and air transportation, moisture-proof, rust-proof, and shock-proof.

b. Transportation mode: sea and air transportation, transportation responsibilities are determined by the terms of the contract.

c. Each package box is accompanied by a detailed packing list and quality certificate. The relevant instructions and all other documents and materials are attached to the package box.

d. The delivery location is the location specified by the customer.

3. Training

The company provides free technical training. After installation and commissioning, our company's technical personnel will provide technical training for your company's operators for no less than 2 days until the operators can use the equipment normally. The main training contents are as follows:

1) Basic knowledge and principles of robot;

2) The structure, operation, maintenance and care of robot;

3) Electrical principles, operation, programming and general fault diagnosis of control systems;

4) Robot arc welding process;

5) Equipment operation and daily maintenance;

6) Welding processing safety education.

4. After-sales service

1. After the equipment is accepted, the warranty period of the whole machine is one year. If there are any problems with the system during the warranty period, our company's technical engineers will provide telephone or video services at any time.

2. During the warranty period of the equipment, our company is responsible for providing free replacement parts and repair services for any damage or damage caused by the quality of the equipment itself. The transportation costs of the parts shall be borne by the customer, except for conventional consumables (such as optical lenses, protective lenses) and accidents caused by user's illegal operation.

3. Our company provides lifelong maintenance services for the products provided, and provides daily consultation and guidance on equipment at any time. Outside the warranty period, our company still provides customers with extensive and preferential technical support and spare parts supply.

4. Our company reserves high-quality operation and maintenance technicians who have been strictly trained by our company for customers for free for a long time, and is always ready to serve customers. Solve the troubles of customers looking for technicians.

5. After the equipment leaves the factory, our company regularly tracks and records the relevant information of the user's use of the equipment. After the equipment maintenance service is completed, our company will report the cause of the fault, remedial measures, completion of maintenance and restoration time and date to the demander.

6. Our company promises to inform the demander of software upgrades in a timely manner and provide software upgrade services free of charge.

7. Our company regularly arranges technicians to provide free technical return visits to users.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Azərbaycan dili

Беларуская мова