The light path at the bottom of the sensor must not be blocked, otherwise it will affect the laser emission and signal recovery and reduce the accuracy. Figure 11 shows the space required for the sensor to work normally. The visual range, laser width and accuracy of each sensor are different, you can select the appropriate sensor according to the requirements according to the following table.

Collaboration Cobot MIG Welding: Features, Applications, and Pricing You Need to Know

Meta Description: Discover how collaboration cobots (cobots) for MIG welding can boost productivity, safety, and ROI. Explore key features, typical price ranges, and buying considerations for modern welding automation.

Introduction

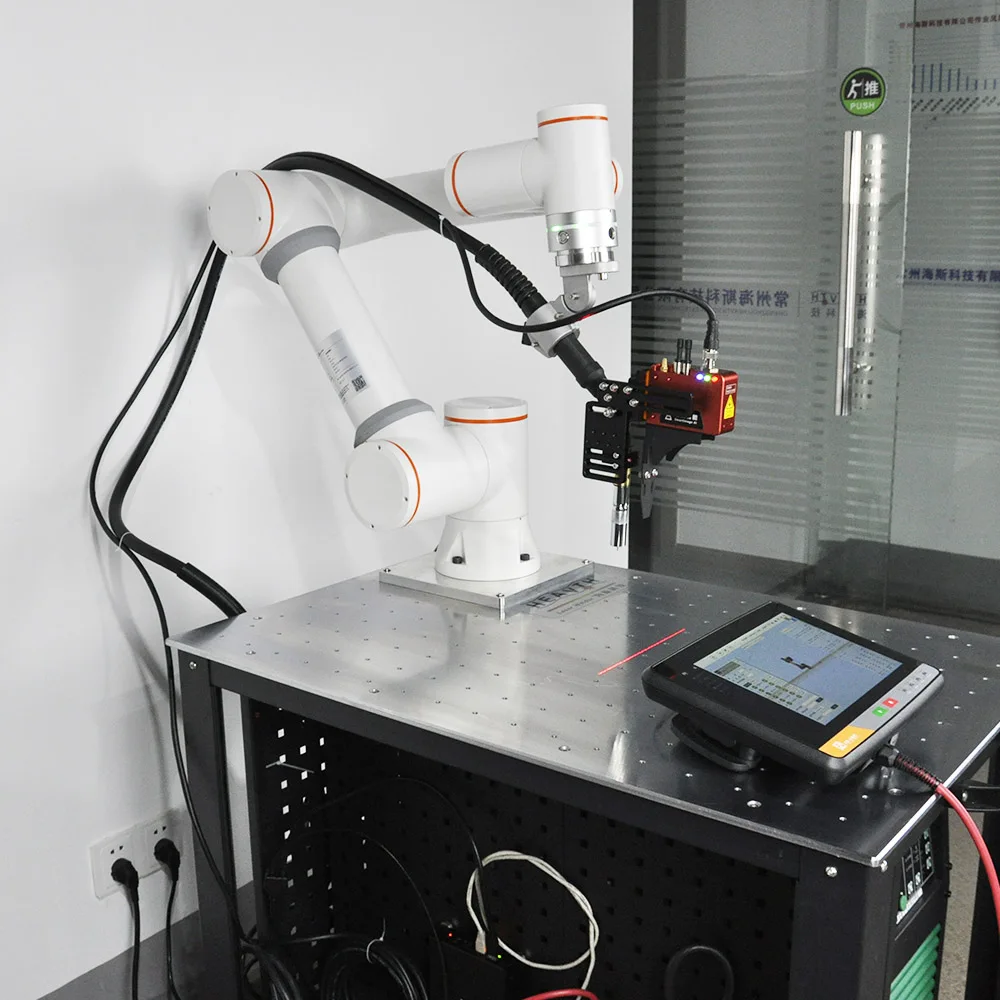

Collaborative robots (cobots) are increasingly used to enhance MIG welding processes in automotive, metal fabrication, and consumer electronics industries. By pairing human expertise with intelligent automation, collaboration cobots deliver consistent weld quality, improved safety, and faster ROI. In this article, we break down what a collaboration cobot for MIG welding is, the typical price ranges, factors that influence cost, and how to choose the right solution for your shop floor.

What is a Collaboration Cobot for MIG Welding?

Definition: A collaboration cobot is a collaborative robot designed to work alongside humans in shared workspaces. In MIG welding applications, cobots handle repetitive or high-precision welds, while human welders focus on setup, inspection, and complex tasks.

Core capabilities: Robotic arm with MIG welding torch integration, advanced safety features (PF readings like force/torque limits, emergency stop, safety-rated monitored live time), offline/online programming, path optimization, real-time monitoring of arc quality, and easy reprogramming for different parts.

Benefits in MIG welding: Consistent welds, reduced cycle times, lower weld fatigue for workers, improved safety in hazardous environments, and scalable automation as demand grows.

Pricing Landscape: What You Should Expect

Note: Actual prices vary by region, brand, payload, reach, power requirements, and included safety and software features. The ranges below are indicative for new systems and may differ for used or refurbished units.

Entry-level MIG welding cobots (compact payload, limited reach): $5,000 – $10,000 per cell

Includes cobot arm, MIG welding torch interface, basic safety enclosure, and entry-level programming software.

Mid-range MIG welding cobots (higher payload, longer reach, enhanced safety): $60,000 – $120,000 per cell

Often includes improved end-effectors, UI, offline programming, and integration with wire feeders and power sources.

High-end / multi-robot cells or specialized configurations: $120,000 – $300,000+ per cell

Includes advanced safety systems, vision guidance, dual-robot coordination, sophisticated path planning, and comprehensive integration with existing welding equipment.

Total cost of ownership considerations:

Software and updates: licensing for path optimization, simulation, and connectivity

Safety equipment: fencing, curtains, sensors, and risk assessment

Install, integration, and commissioning: pay attention to onboarding and training

Spare parts and maintenance: expected wear parts for the torch, grippers, and cables

Operating costs: electricity, shielding gas, consumables, and shield gas efficiency

Key cost-influencing factors

Payload, reach, and repeatability: Higher specs generally cost more but deliver more versatility

Safety features and compliance: Additional sensors, vision systems, and certifications add to price

Integration complexity: Custom fixtures, PLC integration, MES/ERP connectivity, and camera/vision systems

Software depth: Offline programming, simulation, collision detection, and predictive maintenance

Service and support: Onsite installation, training, and long-term support plans

Selecting the Right MIG Welding Cobot: Quick Guide

Define your application: Part size, welding position, material types, and required weld quality

Assess throughput goals: Target cycle times and how many shifts or parts per day

Consider space constraints: Cell footprint, ceiling height, and safety zoning

Prioritize safety compliance: Ensure the cobot solution meets local safety standards and can be integrated with required guarding

Plan for integration: Wire feeders, power sources, and fume extraction as part of a single automation ecosystem

Calculate ROI: Compare labor savings, quality improvements, downtime reductions, and maintenance costs over a defined horizon

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Azərbaycan dili

Беларуская мова