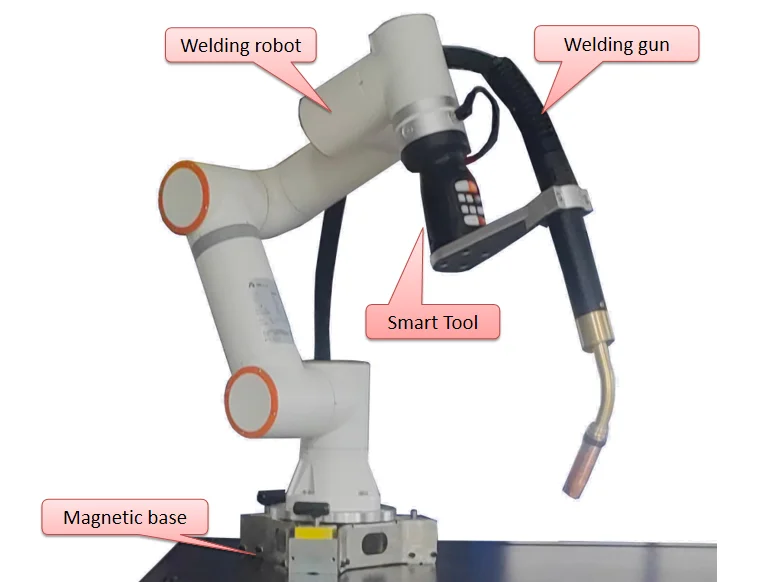

Cobot Smart Handle

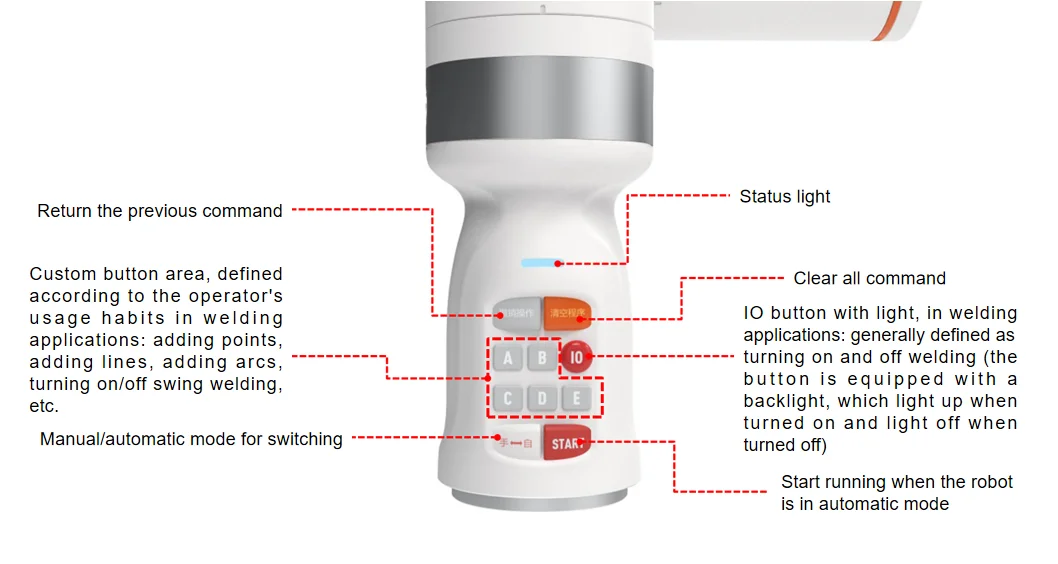

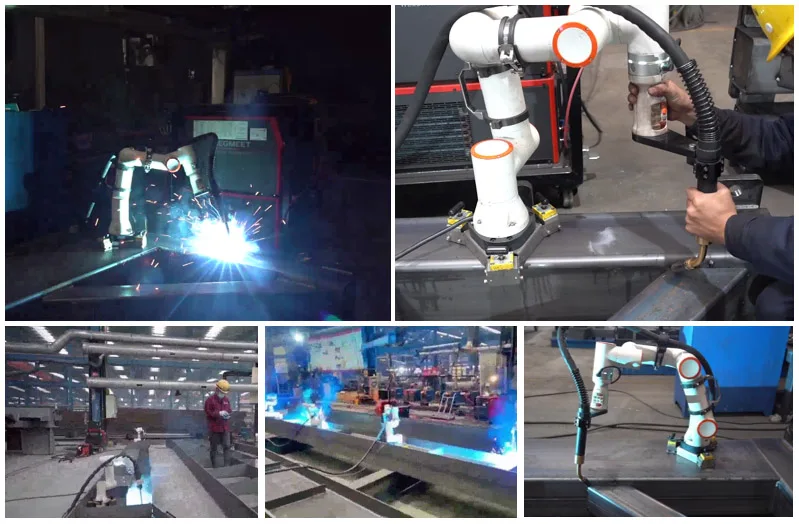

Smart Tool is mainly used in welding programming environment. It can quickly set up linear movement instructions, point-to-point movement instructions, circular movement instructions and IO input and output functions, and can quickly program programs at the end of the equipment. In combination with FR collaborative robots, it can greatly reduce the difficulty of learning programming and complex operations, allowing front-line workers to truly become machine operators.