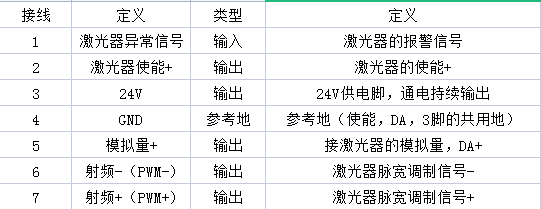

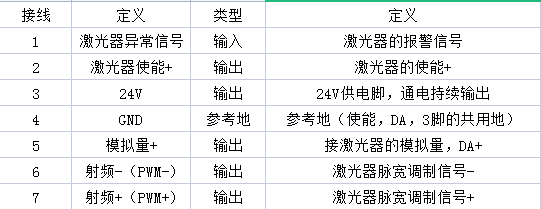

I. Wiring definition of control box

The control box provides the necessary hardwired signal interface and matches the wiring according to the definition provided by the laser manual. Take sup20s handheld welding as an example

As shown in the figure above, the necessary three groups of signals are

2 / 4 pin enable signal, output 24V voltage control signal during operation

4 / 5 pin analog signal, output rated voltage control signal during operation (10V output at full power, output voltage is the peak power of process divided by (total power of laser in the setting interface divided by 10), assuming that the laser power is 2000 and the peak power of process is 1000, the output voltage is 5V)

Pin 6 / 7 is PWM modulation signal, and the output is 24V during operation

Pin 4 is enabled DA. Common ground of pin 3!!!

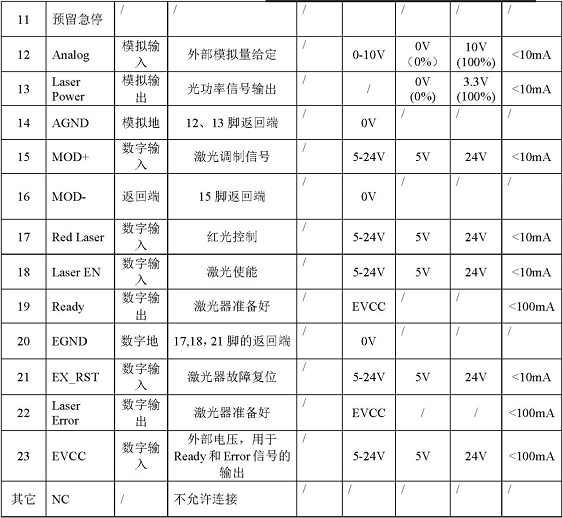

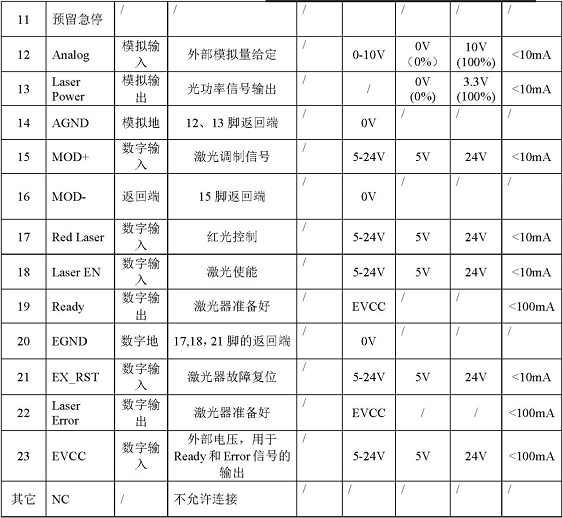

II. Wiring matching of laser

Any laser requires the above three groups of signals, but the manufacturer is different and the wiring definition is different. The wiring should be carried out according to the logic of the laser

(individual lasers need trigger signals, such as red light trigger of individual models of Ruike and the trigger of control mode of Ennai laser, which need 24V and should be connected to pin 3 of the control box)

For example: first look at the definition provided in his manual

In their definition, enable + is pin 18 and enable - is pin 20 (return end of 18)

be

18 connected to 2

20 to 4

Provide enable signal, and so on. After the wiring is completed, conduct light output test. If the laser does not output light, connect the monitoring of the laser to see which signal does not exist, and then conduct corresponding inspection.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Azərbaycan dili

Беларуская мова