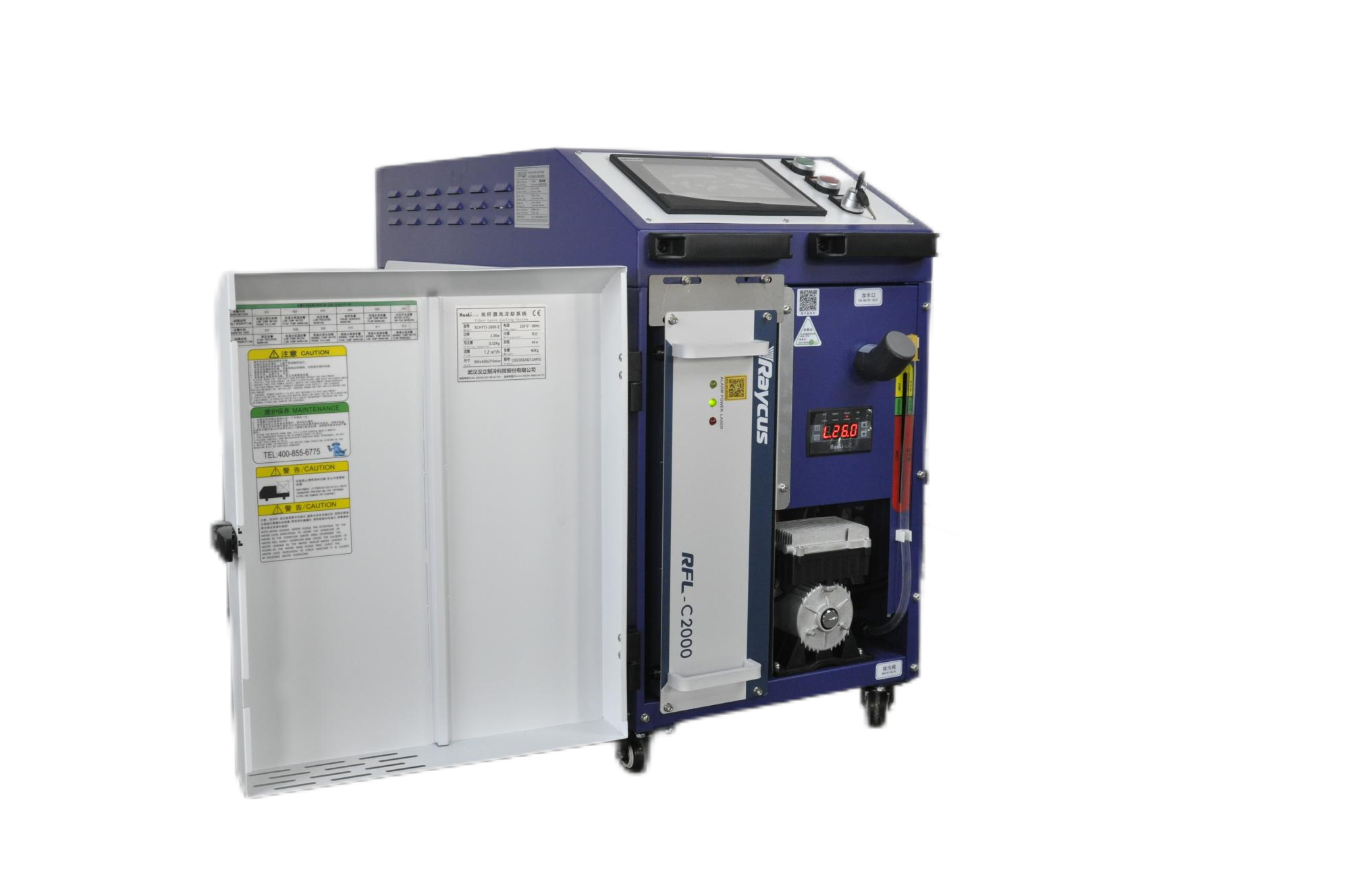

Equipment overview

The HEAVTH handheld laser welding machine is designed for precision and efficiency in welding applications. It combines advanced laser technology with ergonomic design, making it versatile for various welding tasks.

Product features:

Precision Laser Technology:

Utilizes high-powered laser beams for accurate welding with minimal heat distortion.

Handheld Design:

Ergonomic and easy to use, allowing for precise control and maneuverability during welding operations.

Versatile Applications:

Suitable for welding various materials including metals and alloys commonly used in industrial and manufacturing processes.

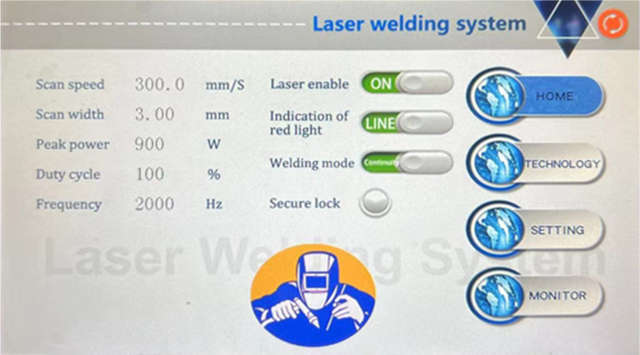

User-Friendly Interface:

Intuitive controls and interface for setting parameters and monitoring welding processes.

Portability:

Lightweight and compact, facilitating mobility and flexibility in different work environments.

Safety Features:

Incorporates safety measures to protect operators and ensure safe handling during operations.

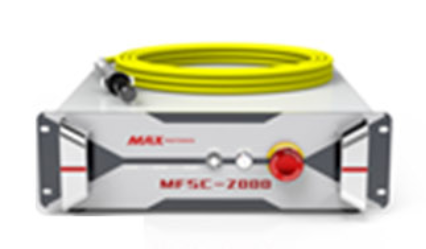

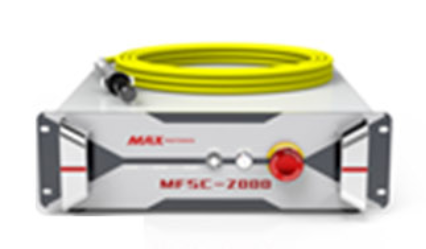

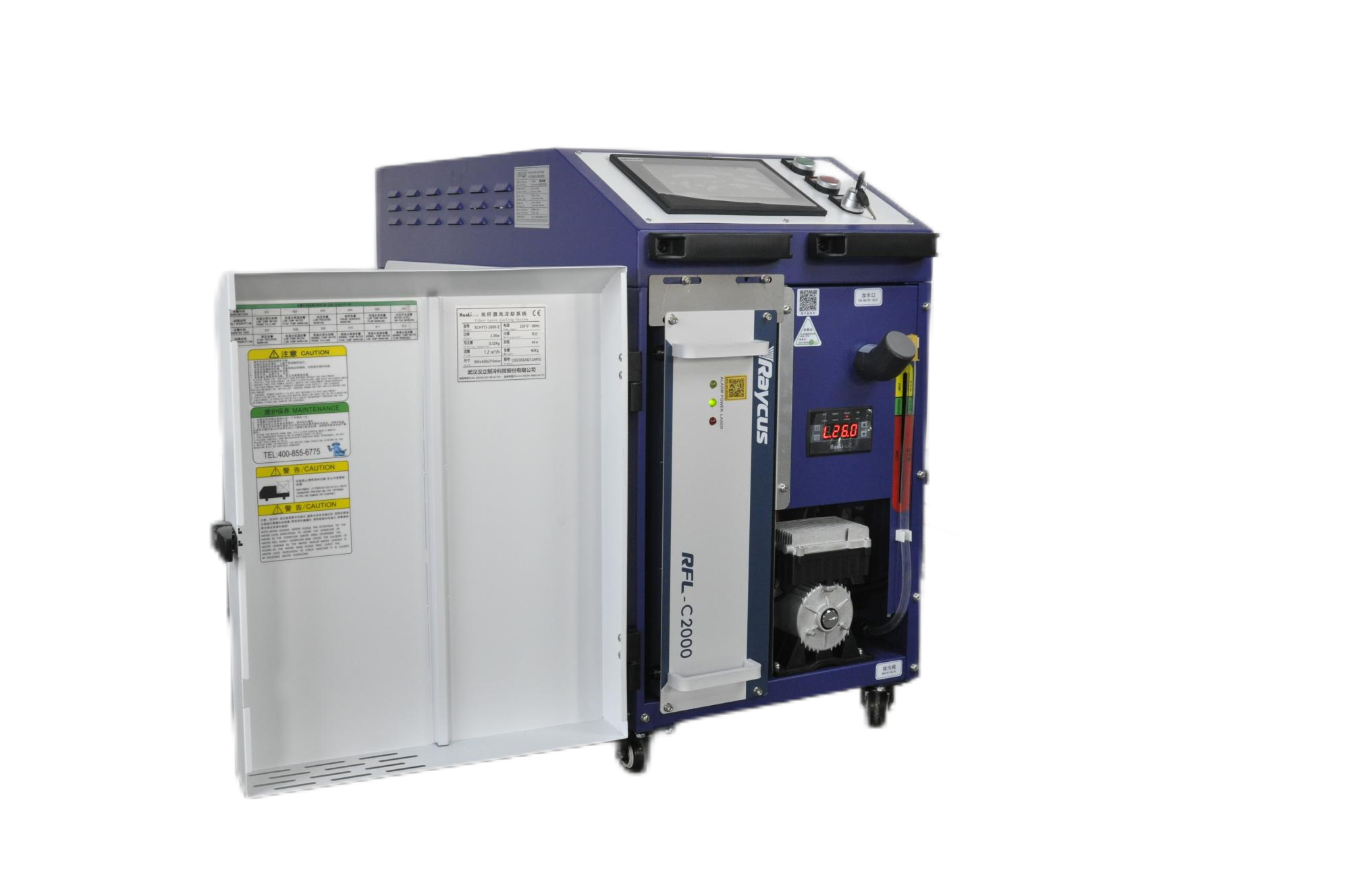

Laser source:

Continuous wave fiber lasers are high-power fiber lasers characterized by high electro-optical conversion efficiency, compact size, good beam quality, and maintenance-free operation. This system uses a small core diameter optical path of 25um-50um, resulting in a small spot size and strong penetration. From the perspective of power density, at the same power level, a finer core diameter leads to higher laser brightness and more concentrated energy.

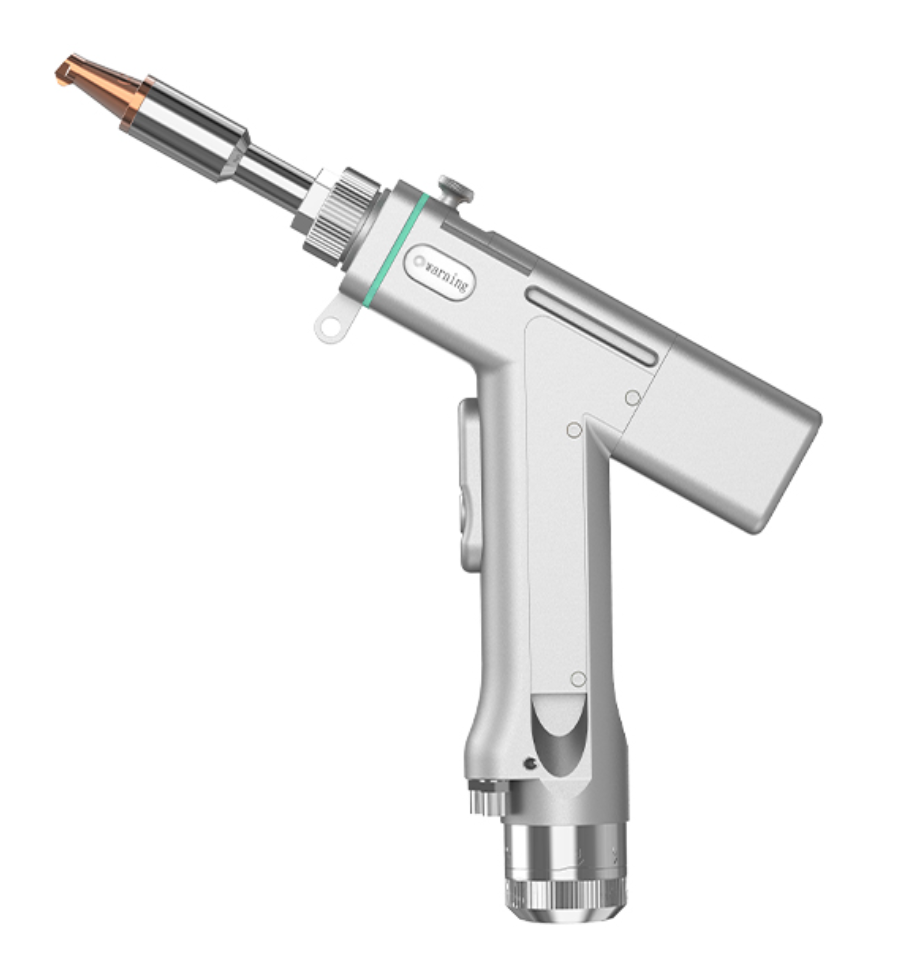

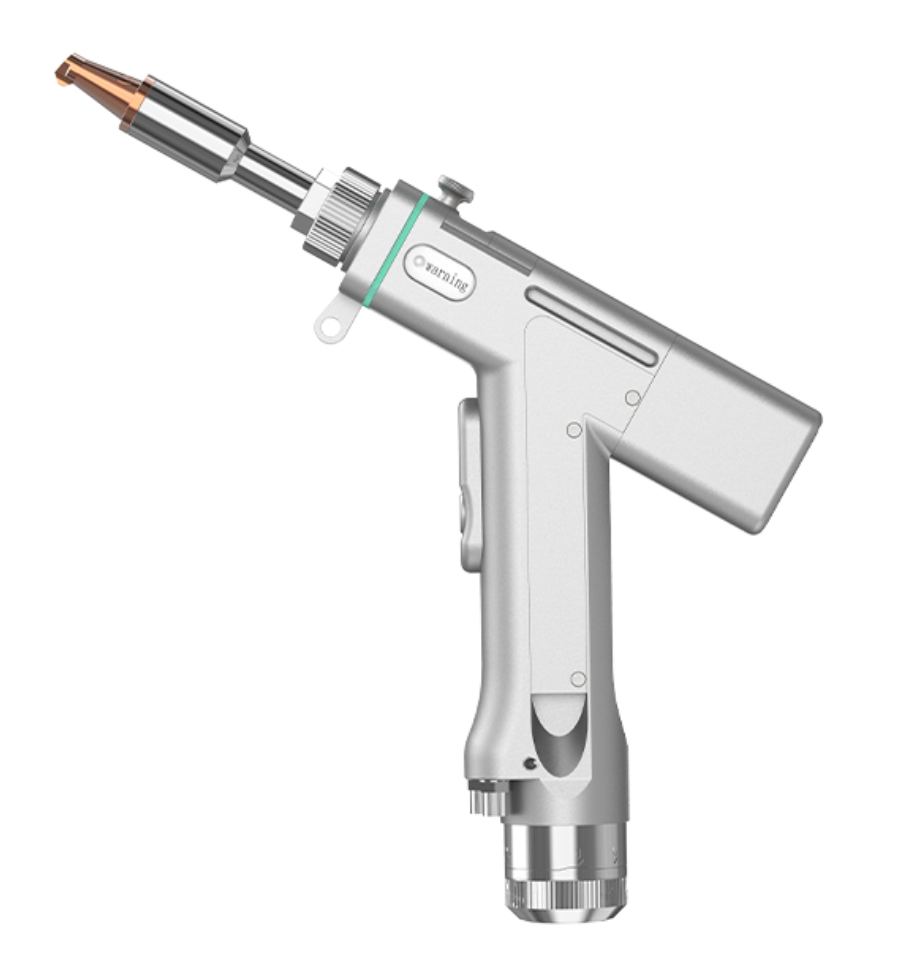

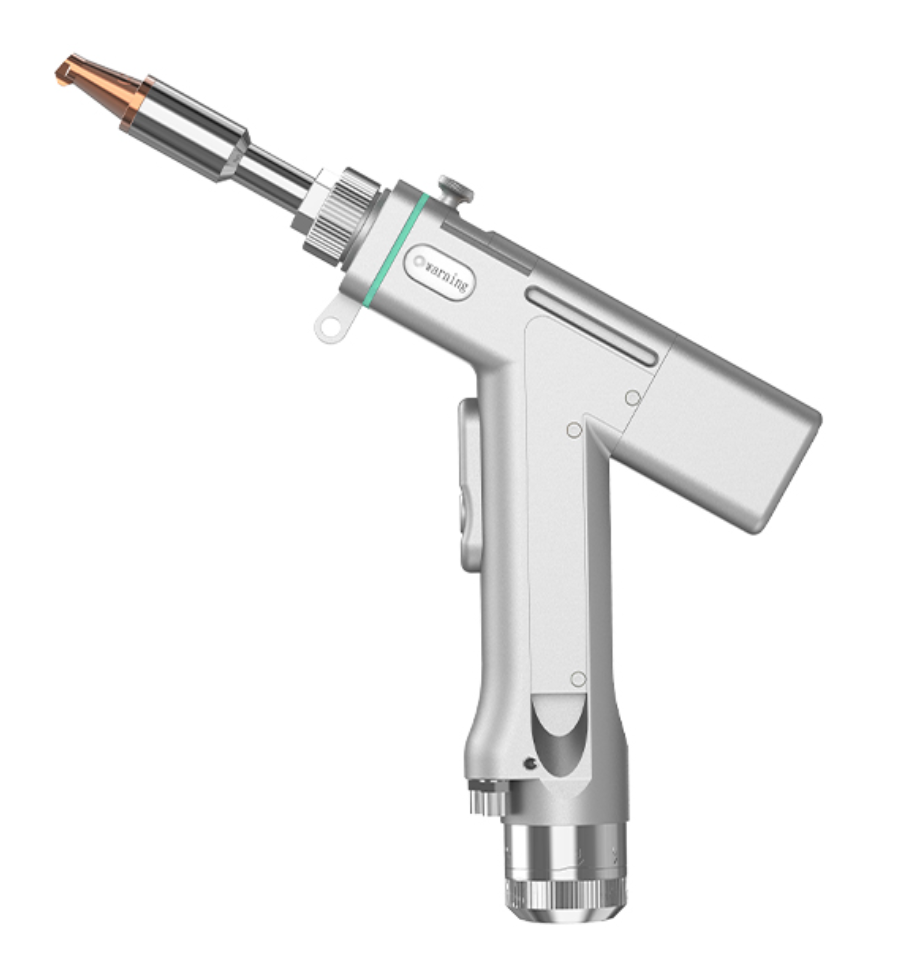

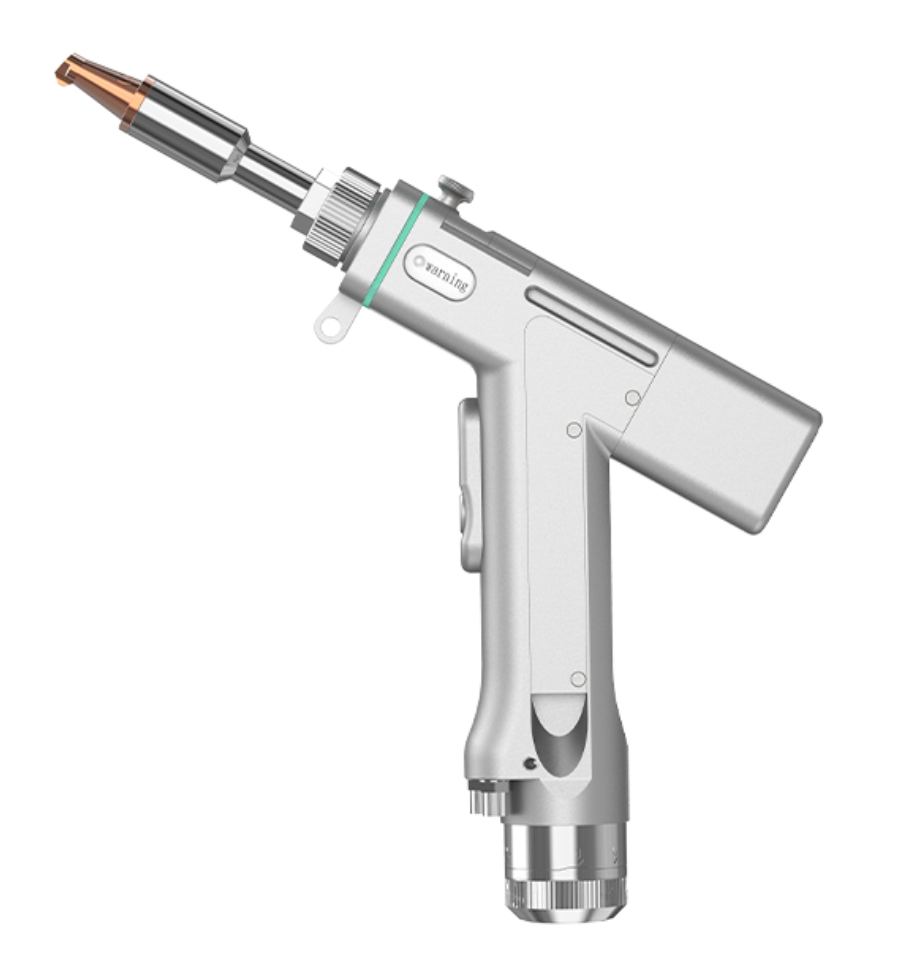

Laser welding head:

1. Features a unique integrated cooling structure and special airflow design, effectively protecting the nozzle and lenses.

2. The welding head's spot size is adjustable, allowing for flexible control over penetration depth and weld bead width.

3. Built-in multi-point temperature measurement, real-time monitoring of welding gun temperature

4. Overall aluminum alloy material, dust-proof, wear-resistant, and anti-interference

5. Quick-release design of the lens for easy inspection and replacement

6. Equipped with a intelligent wire feeder, providing precise wire feeding for high-precision filler wire processes.

|

|

Handheld Laser welding head | Intelligent wire feeder |

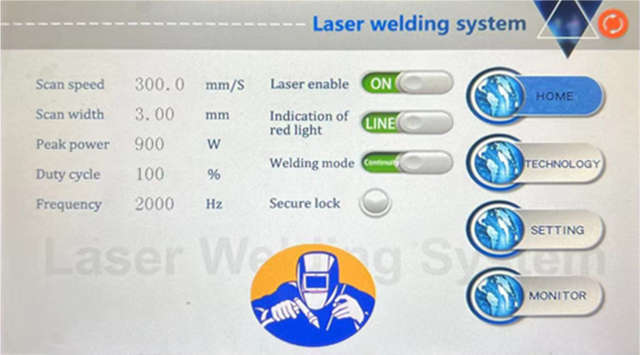

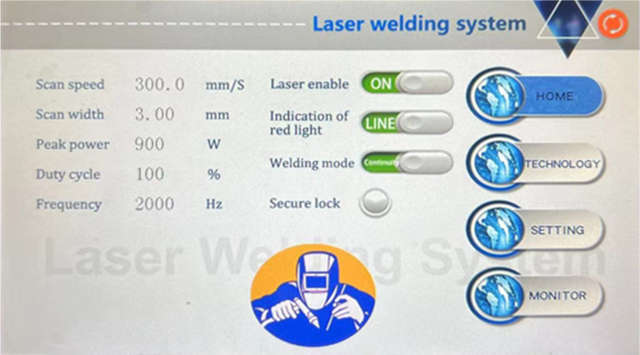

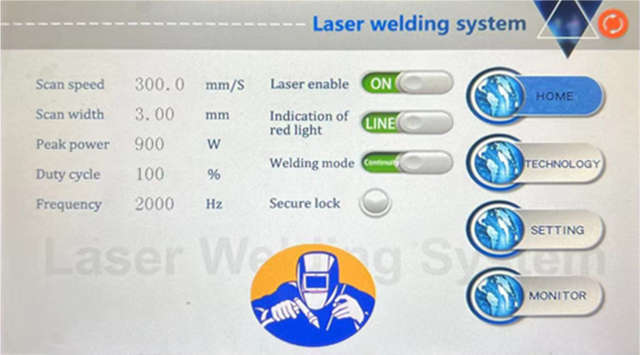

Control system:

The laser welding control system is developed with industrial-grade DSP chip, full-screen touch, and multiple internal parameters are adjustable. The input and output ports are isolated and the anti-interference performance is excellent.

|

|

Multilingual touch screen | Industrial Control Systems |

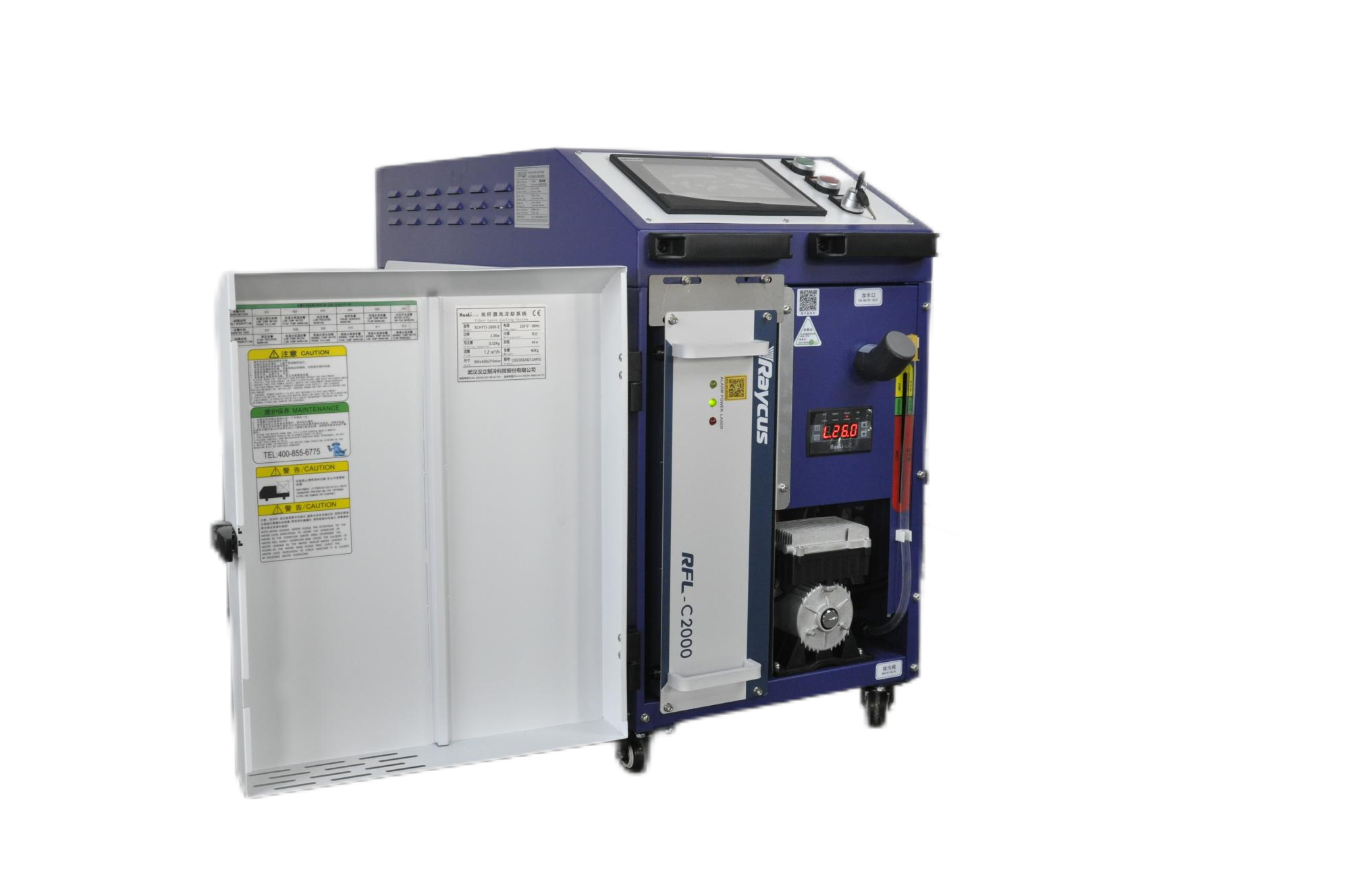

Intelligent Chiller:

In laser welding, the laser is the core component, and it generates a significant amount of heat during operation. The working condition and performance of the chiller directly affect the laser welding effect and stability. To maintain the laser's performance and lifespan, it is crucial to dissipate the heat it generates in a timely manner. Therefore, we utilize a dual-temperature, dual-control, high-capacity chiller for cooling, enabling precise temperature control. The chiller features two independent cooling water circuits: one high-temperature circuit for cooling the laser head and one low-temperature circuit for cooling the laser. With a temperature control accuracy of ±0.1℃, precise temperature control is achieved, ensuring the stability of the laser welding machine's beam output and processing quality, while also extending equipment life and reducing enterprise costs.

Standard configuration:

No. | Name | Description | Quantity |

|

1 | Fiber laser source | Raycus / Max | 1 set |

|

2 | Laser welding system | Sup23 | 1 set |

|

3 | Laser welding head | Sup23T | 1 set |

|

4 | Intelligent wire feeder | Wire feeder with touch screen | 1 set |

|

5 | Water chiller | Hanli | 1 set |

|

6 | Dual wire feeder (Optional) | Increase the filler wire and weld width | 1 sets |

|

Technical parameter:

Model | MS-1000 HLW | MS-1500 HLW | MS-2000 HLW | MS-3000 HLW |

Laser Source | 1000W | 1500W | 2000W | 3000W |

Laser length | 1080nm | 1080nm | 1080nm | 1080nm |

Cable length | 10m | 10m | 10m | 15m |

Fiber core diameter | 25um | 25um | 25um | 50um |

Shielding Gas | Argon, Nitrogen, Air | Argon, Nitrogen, Air | Argon, Nitrogen, Air | Argon, Nitrogen, Air |

Maximum Thickness | 3.5mm | 5mm | 6.5mm | 9mm |

Input Power | 6KW | 7KW | 9.5KW | 12KW |

Water Chiller | 16L 3000W | 16L 3000W | 19L 4000W | 21L 5000W |

Mains Supply | AC220V 1PH | AC220V 1PH | AC220V 1PH | AC380V 3PH |

Welding samples:

Packing list:

Laser Equipment After-Sales Service Terms

1. Installation and commissioning

a. Our technical staff assists customers in the installation and commissioning of equipment. After the goods arrive at the delivery site of the buyer, our engineers provide video technical guidance for the installation and commissioning of the equipment, and assist customers in completing the installation, commissioning, technical indicator testing, training, and delivery of the equipment.

b. Remote installation and commissioning must be completed within the period specified in the contract. All equipment provided in the contract is responsible for docking and completing installation and commissioning by our company. After the equipment is installed and commissioned, the customer shall conduct a self-inspection of the equipment and ensure that all technical indicators meet the technical requirements.

c. For customers who need on-site installation and training, the customer shall bear the transportation costs to and from the commissioning site, and the technical staff service fee is US$200 per day, calculated from the departure of the company to the return (i.e. on-site service time + round-trip transportation time).

2. Packaging and transportation

a. Standard export packaging, suitable for long-distance sea and air transportation, moisture-proof, rust-proof, and shock-proof.

b. Transportation mode: sea and air transportation, transportation responsibilities are determined by the terms of the contract.

c. Each package box is accompanied by a detailed packing list and quality certificate. The relevant instructions and all other documents and materials are attached to the package box.

d. The delivery location is the location specified by the customer.

3. Training

The company provides free technical training. After installation and commissioning, our company's technical personnel will provide technical training for your company's operators for no less than 2 days until the operators can use the equipment normally. The main training contents are as follows:

1) Basic knowledge and principles of lasers;

2) The structure, operation, maintenance and care of lasers;

3) Electrical principles, operation, programming and general fault diagnosis of CNC systems;

4) Laser welding process;

5) Equipment operation and daily maintenance;

6) Laser processing safety education.

4. After-sales service

1. After the equipment is accepted, the warranty period of the whole machine is one year. If there are any problems with the system during the warranty period, our company's technical engineers will provide telephone or video services at any time.

2. During the warranty period of the equipment, our company is responsible for providing free replacement parts and repair services for any damage or damage caused by the quality of the equipment itself. The transportation costs of the parts shall be borne by the customer, except for conventional consumables (such as optical lenses, protective lenses) and accidents caused by user's illegal operation.

3. Our company provides lifelong maintenance services for the products provided, and provides daily consultation and guidance on equipment at any time. Outside the warranty period, our company still provides customers with extensive and preferential technical support and spare parts supply.

4. Our company reserves high-quality operation and maintenance technicians who have been strictly trained by our company for customers for free for a long time, and is always ready to serve customers. Solve the troubles of customers looking for technicians.

5. After the equipment leaves the factory, our company regularly tracks and records the relevant information of the user's use of the equipment. After the equipment maintenance service is completed, our company will report the cause of the fault, remedial measures, completion of maintenance and restoration time and date to the demander.

6. Our company promises to inform the demander of software upgrades in a timely manner and provide software upgrade services free of charge.

7. Our company regularly arranges technicians to provide free technical return visits to users.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Azərbaycan dili

Беларуская мова