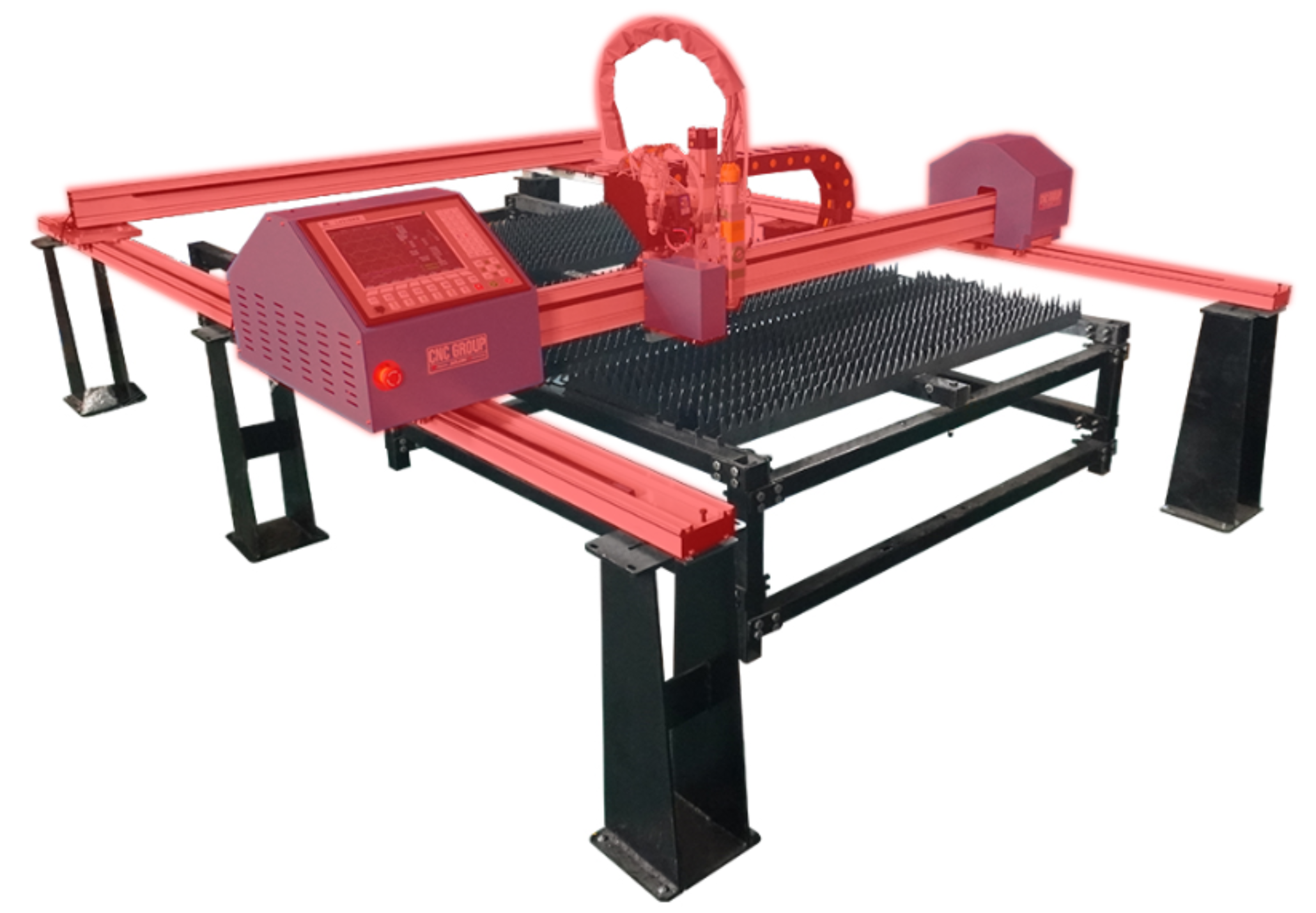

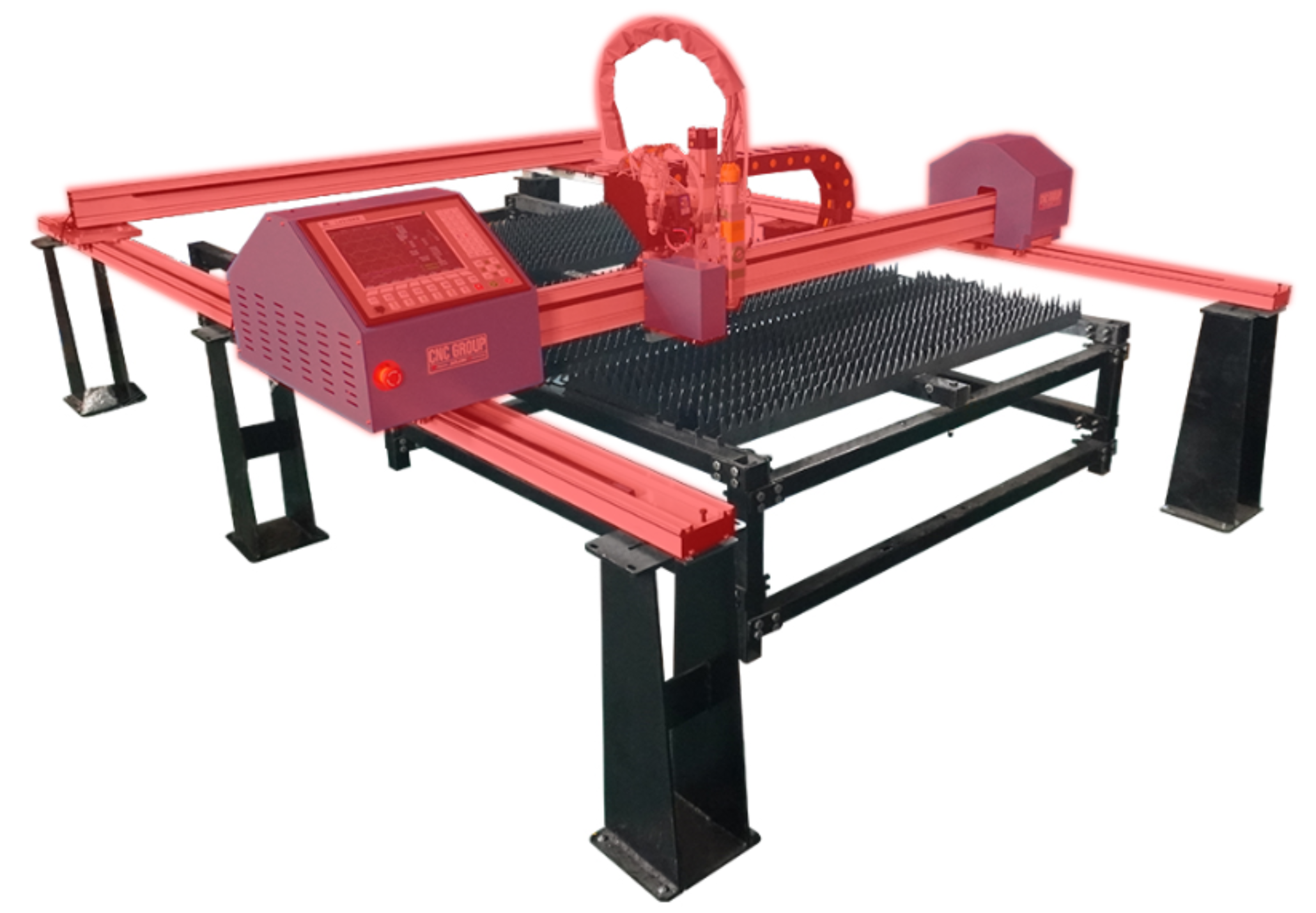

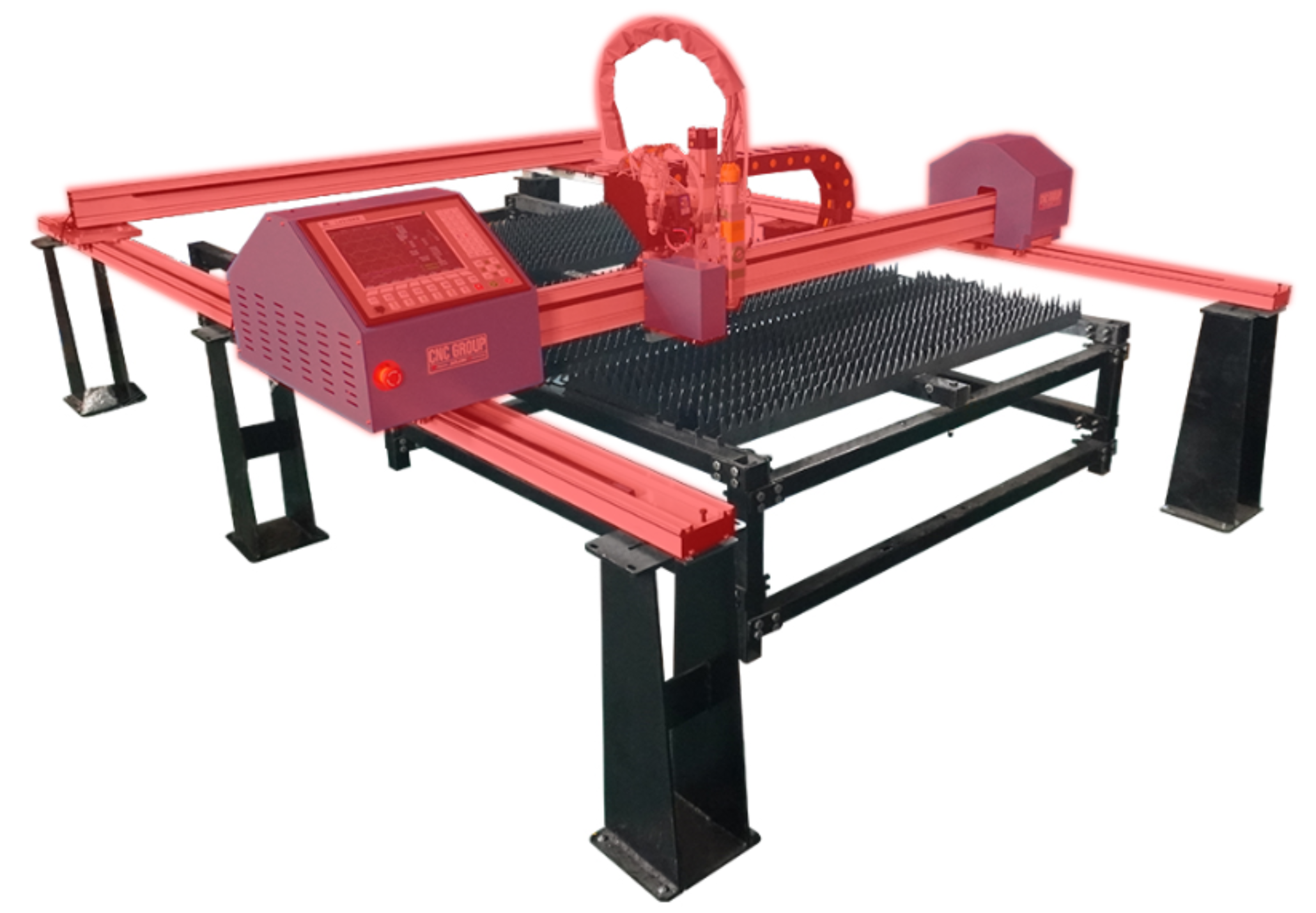

Equipment overview

This portable gantry laser cutting machine is designed for small and medium-sized enterprises and on-site operation needs. It integrates high precision, high efficiency and high flexibility. It adopts advanced laser technology and gantry structure design. It has fast cutting speed, smooth cutting seam and small thermal deformation. It is suitable for a variety of metal materials such as stainless steel, carbon steel, aluminum alloy, etc. The whole machine is modularly designed, easy to install and move, and can be easily operated without a large factory. It is an ideal choice for industries such as metal processing sheet metal manufacturing equipment maintenance.

Product features:

Portable design:

Easy transportation, fast deployment, suitable for a variety of work scenarios.

Precision cutting:

High-power laser supports high-speed, high-precision cutting, and the incision is smooth.

Easy operation:

Intelligent control system, support for multiple file formats, one-button start.

Energy Saving and high efficiency:

Optimize energy consumption control and reduce operating costs.

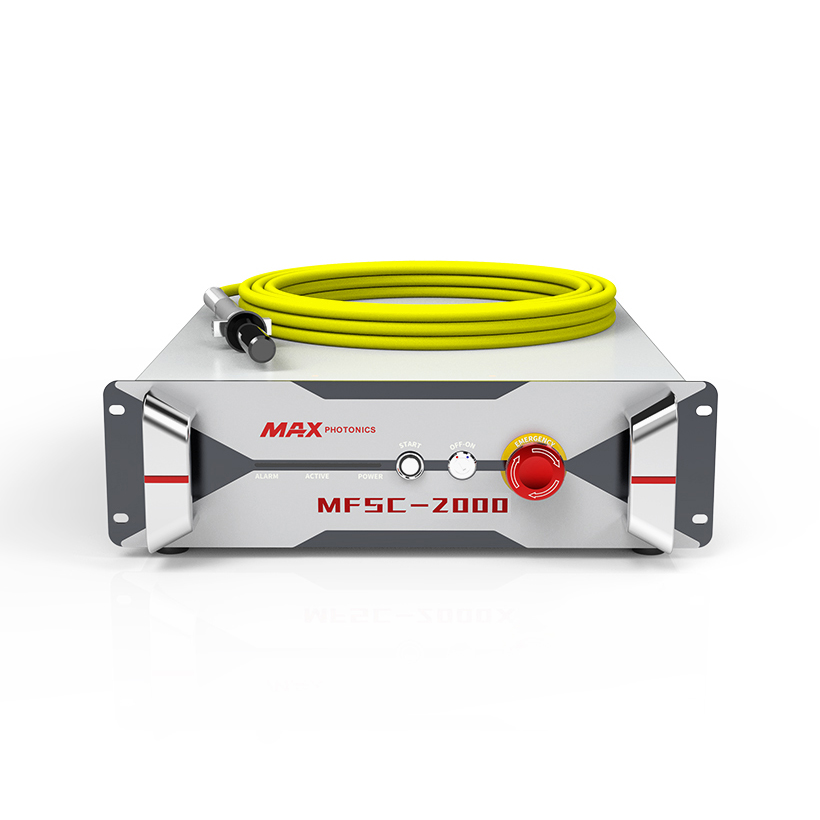

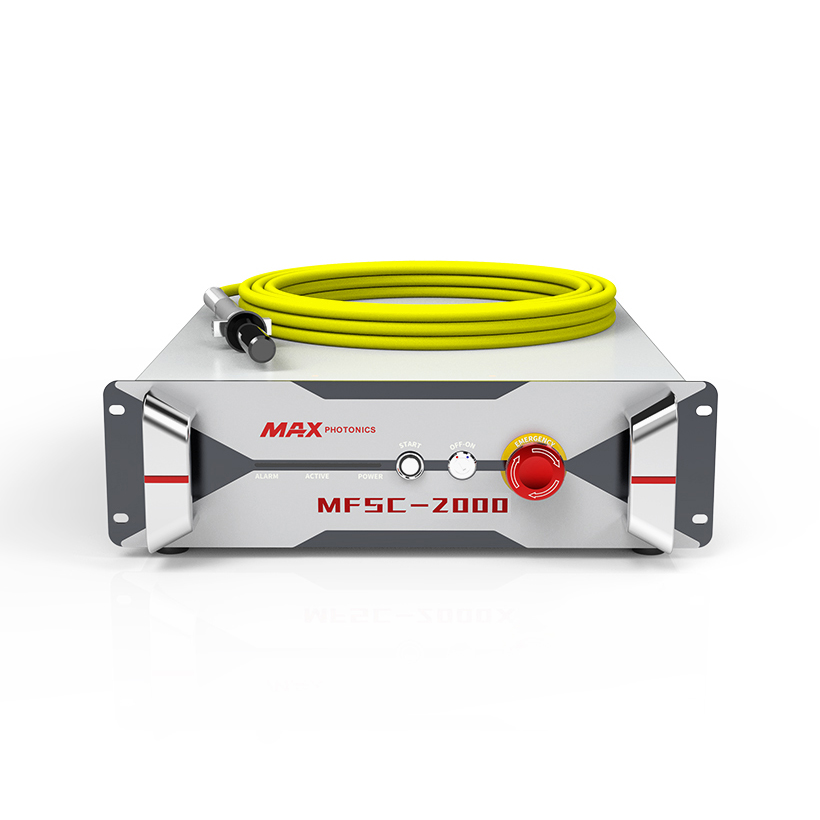

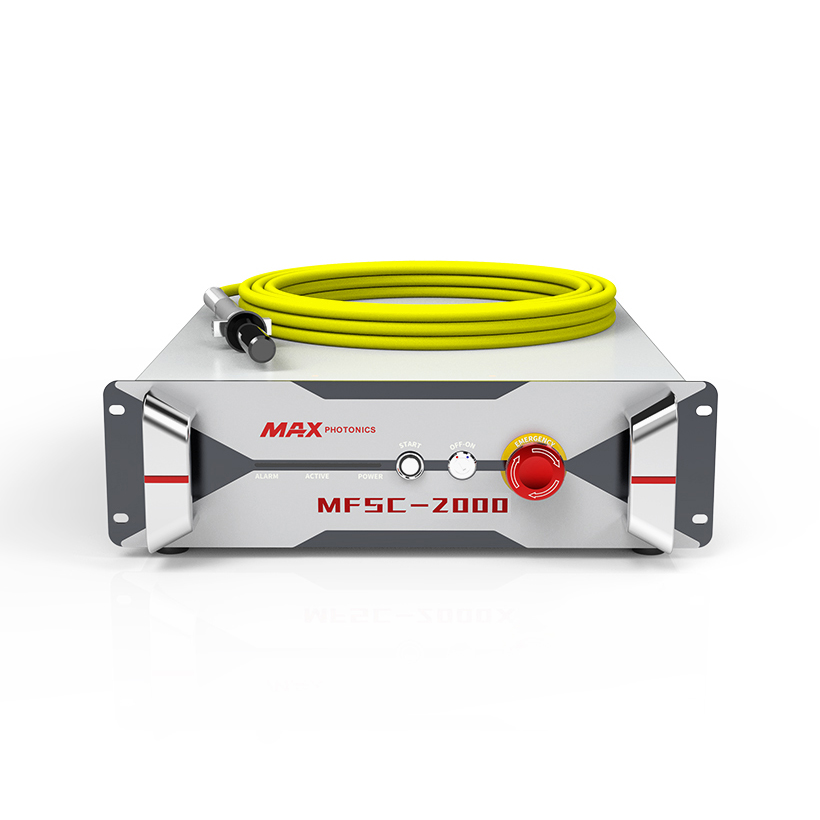

Laser source:

1000W~6000W single module CW fiber laser is a high-power fiber laser with high electro-optical conversion efficiency, compact size, good beam quality and maintenance-free. Wide fiber core diameter range from 100~600um, can be customized from 800um~1000um. Mainly used in metal cutting, welding and cladding and other fields such as new energy, 3C, precision machining.

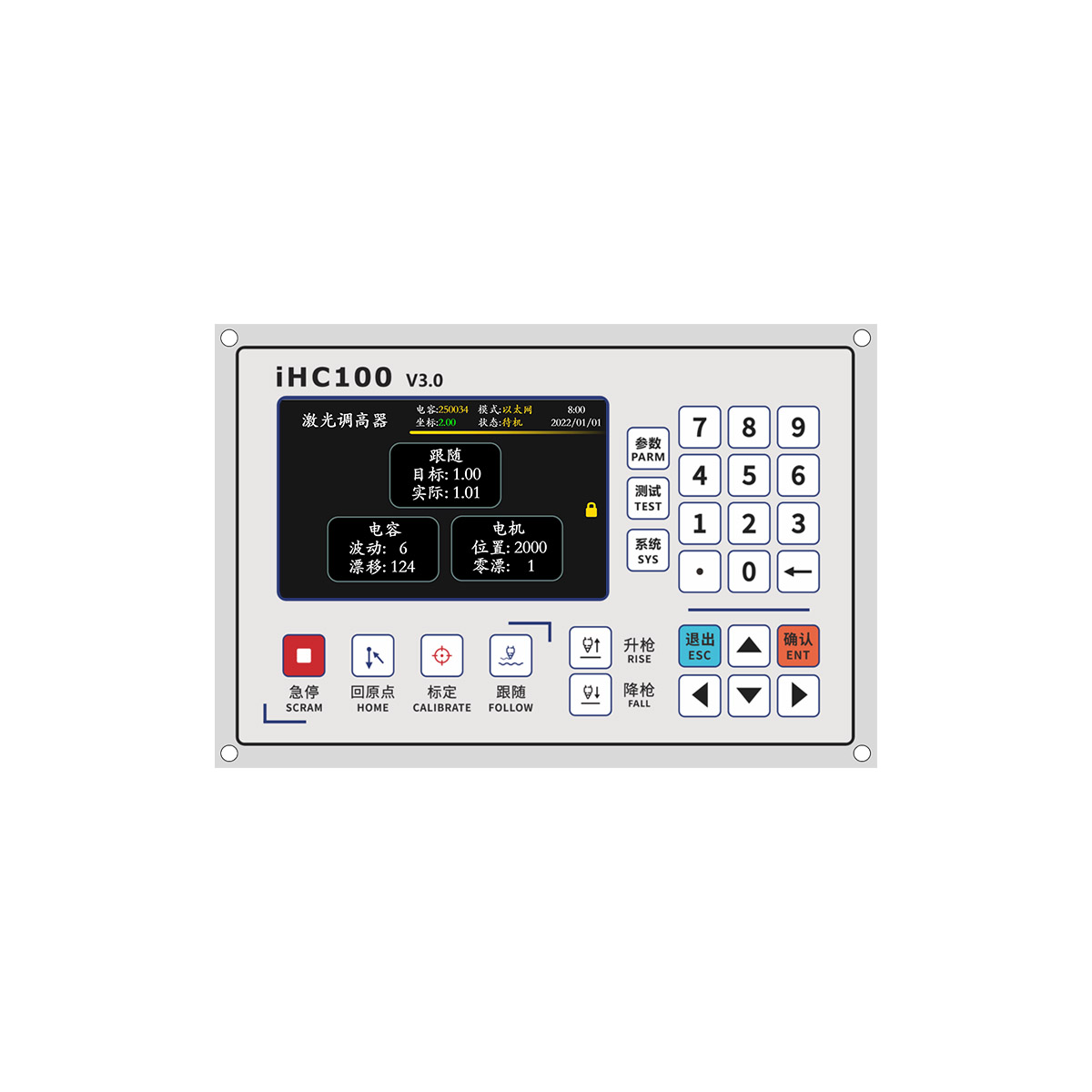

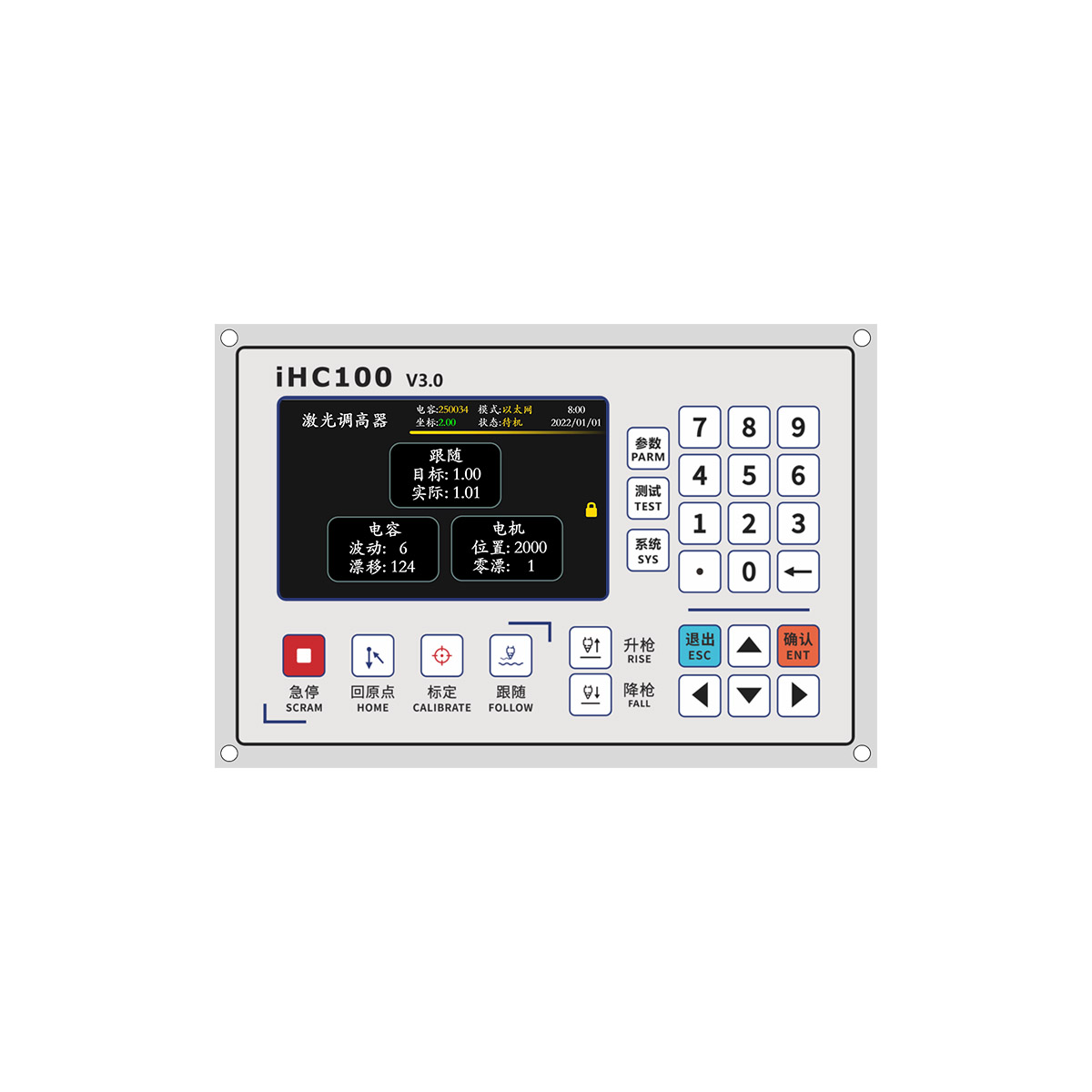

Laser cutting head:

Laser cutting head can be quickly positioned, follow according to the height of the plate, shorten the perforation time, high speed cutting. And it can change auto-focus head.

|

|

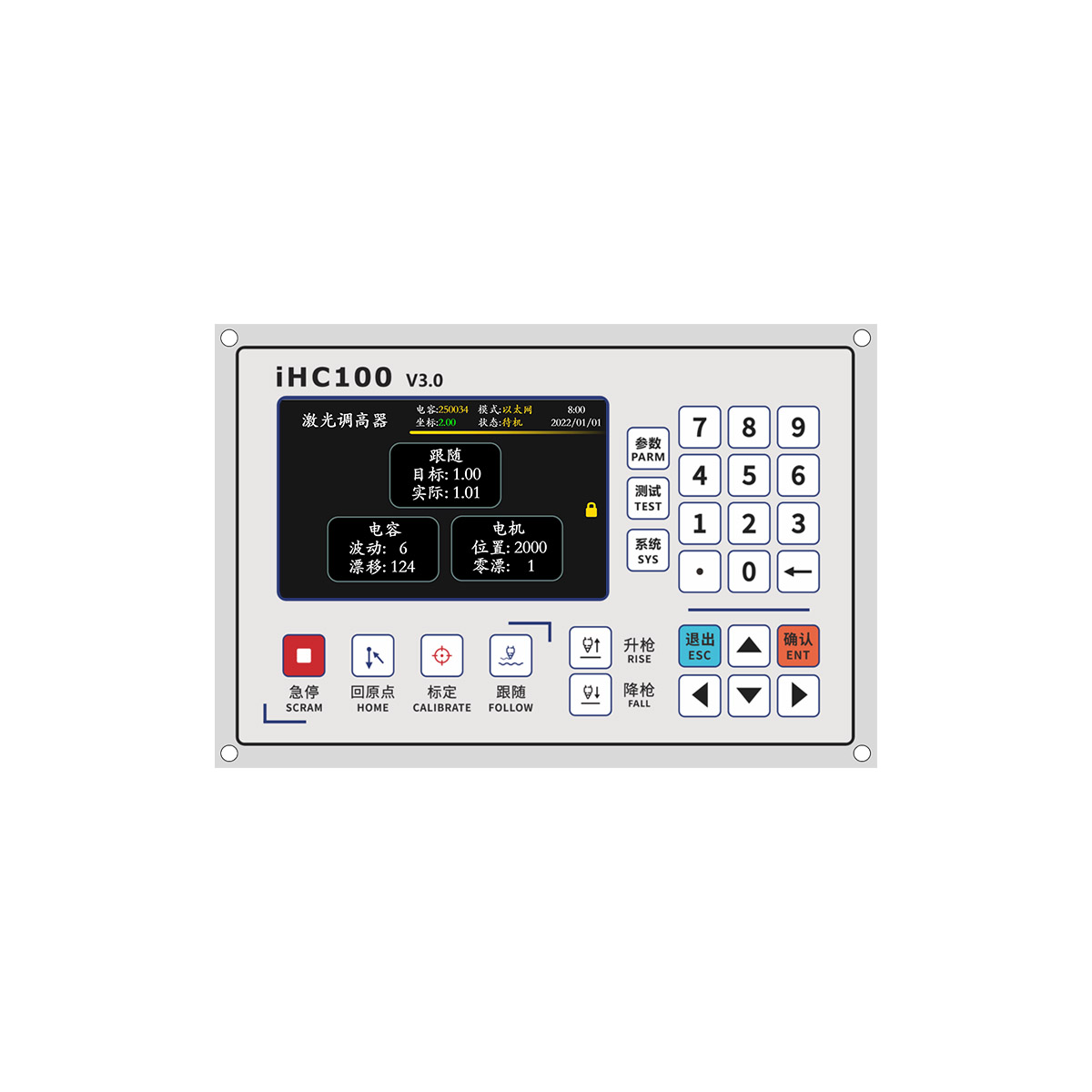

Laser head height controller | Laser cutting head |

Laser CNC system:

Our laser CNC system using the latest low laser special operating system, full screen touch, can be external keyboard and mouse, simple operation, easy to use.

Separation of the guide rail material table:

The overall structure is compact, the operation and maintenance are convenient, and the material table can be offered by the supplier or be made by the customer to save the cost.

Basic configuration:

No. | Name | Description | Quantity |

|

1 | Fiber laser source | Raycus / Max | 1 set |

|

2 | Laser CNC system | Fang Ling | 1 set |

|

3 | Laser cutting head | Ospri / RayTools | 1 set |

|

4 | Laser head height control | Capacitive height control | 1 set |

|

5 | Water chiller | Hanli / S&A | 1 set |

|

6 | Motor / Drive | Starter servo motor | 3 sets |

|

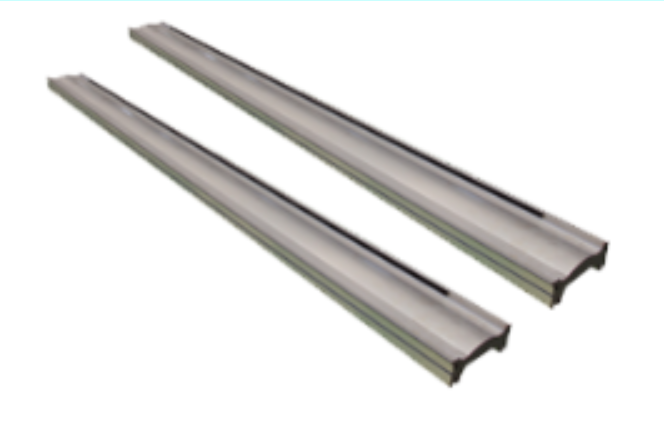

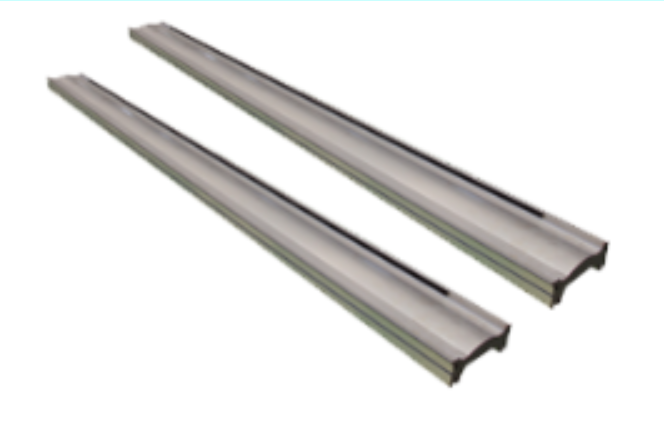

7 | Rails | Aluminum alloy with linear | 1 set |

|

8 | Machine table and base | Optional | 1 set |

|

9 | Remote controller | Optional | 1 set |

|

Technical parameter:

Product Model | MFL3015-15K | MFL6020-15K | MFL3015-20K | MFL6020-20K | MFL3015-30K | MFL6020-30K |

Laser Source | 1.5kW | 1.5kW | 2kW | 2kW | 3kW | 3kW |

Cutting Width | 1500mm | 2000mm | 1500mm | 2000mm | 1500mm | 2000mm |

Cutting Length | 3000mm | 6000mm | 3000mm | 6000mm | 3000mm | 6000mm |

Cutting Capacity | 16mm, 5/8" | 16mm, 5/8" | 20mm, 3/4" | 20mm, 3/4" | 25mm, 1" | 25mm, 1" |

X axis Rail Length | 2000mm | 2500mm | 2000mm | 2500mm | 2000mm | 2500mm |

Y axis Rail Length | 3500mm | 6500mm | 3500mm | 6500mm | 3500mm | 6500mm |

Power Supply | AC220V 1PH | AC220V 1PH | AC220V 1PH | AC220V 1PH | AC380V 3PH | AC380V 3PH |

Movement Accuracy | ±0.4mm/m |

Maximum Speed | 8,000 mm/min (320 IPM) |

CNC Controller | Arm CNC System For Laser Cutting |

Control motor | X-axis: Servo Motor, Y-axis: Dual Servo motor |

Cuttting samples:

Packing Size:

Model: MFL3015-15K |

Description | Size | Quantity |

Laser cutting machine | 2700*700*800mm | 1 |

Y-axis rails | 3800*160*200mm | 1 |

Water Chiller | 600*500*760mm | 1 |

Laser Equipment After-Sales Service Terms

1. Installation and commissioning

a. Our technical staff assists customers in the installation and commissioning of equipment. After the goods arrive at the delivery site of the buyer, our engineers provide video technical guidance for the installation and commissioning of the equipment, and assist customers in completing the installation, commissioning, technical indicator testing, training, and delivery of the equipment.

b. Remote installation and commissioning must be completed within the period specified in the contract. All equipment provided in the contract is responsible for docking and completing installation and commissioning by our company. After the equipment is installed and commissioned, the customer shall conduct a self-inspection of the equipment and ensure that all technical indicators meet the technical requirements.

c. For customers who need on-site installation and training, the customer shall bear the transportation costs to and from the commissioning site, and the technical staff service fee is US$200 per day, calculated from the departure of the company to the return (i.e. on-site service time + round-trip transportation time).

2. Packaging and transportation

a. Standard export packaging, suitable for long-distance sea and air transportation, moisture-proof, rust-proof, and shock-proof.

b. Transportation mode: sea and air transportation, transportation responsibilities are determined by the terms of the contract.

c. Each package box is accompanied by a detailed packing list and quality certificate. The relevant instructions and all other documents and materials are attached to the package box.

d. The delivery location is the location specified by the customer.

3. Training

The company provides free technical training. After installation and commissioning, our company's technical personnel will provide technical training for your company's operators for no less than 2 days until the operators can use the equipment normally. The main training contents are as follows:

1) Basic knowledge and principles of lasers;

2) The structure, operation, maintenance and care of lasers;

3) Electrical principles, operation, programming and general fault diagnosis of CNC systems;

4) Laser welding process;

5) Equipment operation and daily maintenance;

6) Laser processing safety education.

4. After-sales service

1. After the equipment is accepted, the warranty period of the whole machine is one year. If there are any problems with the system during the warranty period, our company's technical engineers will provide telephone or video services at any time.

2. During the warranty period of the equipment, our company is responsible for providing free replacement parts and repair services for any damage or damage caused by the quality of the equipment itself. The transportation costs of the parts shall be borne by the customer, except for conventional consumables (such as optical lenses, protective lenses) and accidents caused by user's illegal operation.

3. Our company provides lifelong maintenance services for the products provided, and provides daily consultation and guidance on equipment at any time. Outside the warranty period, our company still provides customers with extensive and preferential technical support and spare parts supply.

4. Our company reserves high-quality operation and maintenance technicians who have been strictly trained by our company for customers for free for a long time, and is always ready to serve customers. Solve the troubles of customers looking for technicians.

5. After the equipment leaves the factory, our company regularly tracks and records the relevant information of the user's use of the equipment. After the equipment maintenance service is completed, our company will report the cause of the fault, remedial measures, completion of maintenance and restoration time and date to the demander.

6. Our company promises to inform the demander of software upgrades in a timely manner and provide software upgrade services free of charge.

7. Our company regularly arranges technicians to provide free technical return visits to users.

English

简体中文

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ພາສາລາວ

ភាសាខ្មែរ

Bahasa Melayu

ဗမာစာ

Filipino

Bahasa Indonesia

magyar

Română

Čeština

Монгол

қазақ

Српски

हिन्दी

فارسی

Kiswahili

Slovenčina

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

Հայերեն

Latine

Dansk

Shqip

বাংলা

Hrvatski

Afrikaans

Gaeilge

Eesti keel

Oʻzbekcha

latviešu

Aymara

Azərbaycan dili

Беларуская мова